| Availability: | |

|---|---|

| Quantity: | |

Customized

ETERNAL

Product Description

1. Size: Customized

2. Material: Duplex Stainless Steel

3. Heat treatment: Annealing,/Solution/Aging

4. Surface treatment: Polish/Black Surface

5.Shape:Bar /Plate/Flat

6. Transport packaging: Wooden case

7. Warranty period: One year

Application

Marine engineering: Manufacturing structural components for offshore platforms, subsea oil/gas pipelines, ship desulfurization towers, etc., resistant to long-term corrosion from seawater.

Chemical and petrochemical: used in reactors, heat exchangers, pipeline valves, etc., adapted to corrosive media such as acid and alkali, salt solutions, etc.

Desalination of seawater: As the core component of desalination equipment, it resists the erosion of high salt concentration seawater.

Other industries: bleaching towers, steamers, food processing equipment in the paper industry, as well as corrosion-resistant high-strength components in the oil extraction and power generation industries.

Feature

The core characteristics of duplex stainless steel are strong corrosion resistance, excellent mechanical properties, and good weldability. Its applications are concentrated in harsh corrosion and high-strength demand scenarios.

Outstanding corrosion resistance: resistant to chloride stress corrosion and strong pitting corrosion, some grades (super duplex) can cope with harsh media such as strong acids and high salts.

Excellent mechanical properties: The yield strength is twice that of ordinary austenitic stainless steel, combining high fatigue strength and good toughness, and can meet strength requirements without additional thickening.

Good weldability: has a low tendency for hot cracking, does not require preheating before welding, does not require heat treatment after welding, and can also be welded with ordinary stainless steel and carbon steel of different types.

Balanced comprehensive performance: high thermal conductivity, low coefficient of linear expansion, wide range of thermal processing, taking into account the advantages of both ferritic and austenitic stainless steels.

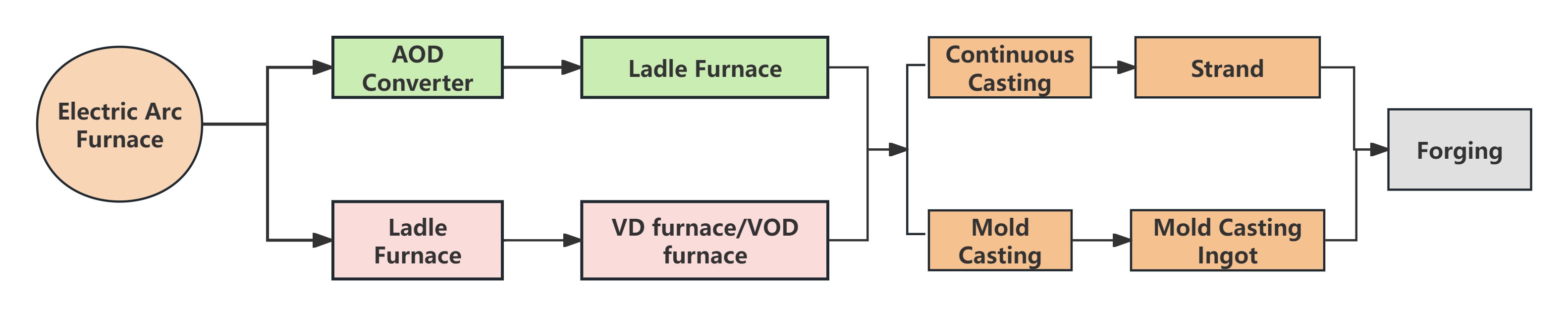

Production Procedure

Steel Grade and Chemical Composition

Product Description

1. Size: Customized

2. Material: Duplex Stainless Steel

3. Heat treatment: Annealing,/Solution/Aging

4. Surface treatment: Polish/Black Surface

5.Shape:Bar /Plate/Flat

6. Transport packaging: Wooden case

7. Warranty period: One year

Application

Marine engineering: Manufacturing structural components for offshore platforms, subsea oil/gas pipelines, ship desulfurization towers, etc., resistant to long-term corrosion from seawater.

Chemical and petrochemical: used in reactors, heat exchangers, pipeline valves, etc., adapted to corrosive media such as acid and alkali, salt solutions, etc.

Desalination of seawater: As the core component of desalination equipment, it resists the erosion of high salt concentration seawater.

Other industries: bleaching towers, steamers, food processing equipment in the paper industry, as well as corrosion-resistant high-strength components in the oil extraction and power generation industries.

Feature

The core characteristics of duplex stainless steel are strong corrosion resistance, excellent mechanical properties, and good weldability. Its applications are concentrated in harsh corrosion and high-strength demand scenarios.

Outstanding corrosion resistance: resistant to chloride stress corrosion and strong pitting corrosion, some grades (super duplex) can cope with harsh media such as strong acids and high salts.

Excellent mechanical properties: The yield strength is twice that of ordinary austenitic stainless steel, combining high fatigue strength and good toughness, and can meet strength requirements without additional thickening.

Good weldability: has a low tendency for hot cracking, does not require preheating before welding, does not require heat treatment after welding, and can also be welded with ordinary stainless steel and carbon steel of different types.

Balanced comprehensive performance: high thermal conductivity, low coefficient of linear expansion, wide range of thermal processing, taking into account the advantages of both ferritic and austenitic stainless steels.

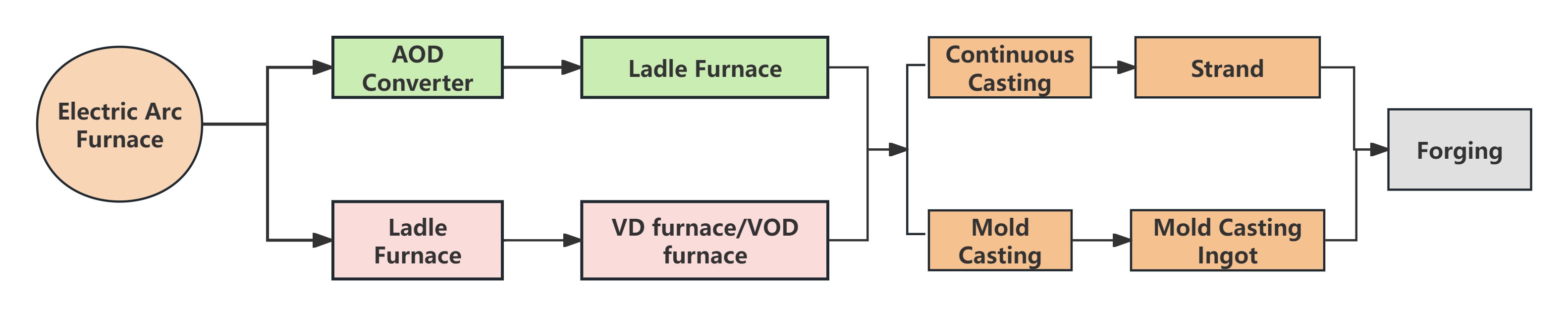

Production Procedure

Steel Grade and Chemical Composition