| Availability: | |

|---|---|

| Quantity: | |

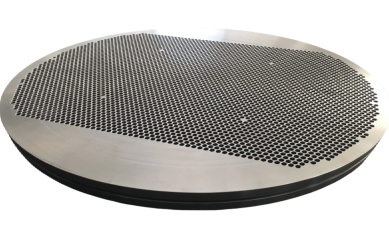

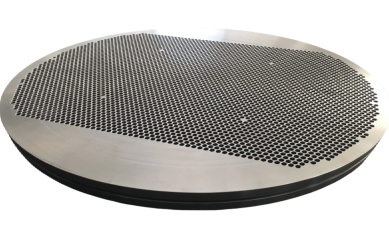

FORGE-TS

ETERNAL

A Forged SUS316L Stainless Steel Tube Sheet is a high-performance industrial spare part crafted from top-grade SUS316L stainless steel via precision forging technology. Unlike cast tube sheets, the forging process enhances the material’s structural density, eliminating internal defects and significantly boosting its mechanical strength and corrosion resistance. This product is engineered to meet the rigorous demands of harsh industrial environments, where reliability, durability, and hygiene are non-negotiable.

The SUS316L stainless steel base material is the key to its superiority—infused with molybdenum (2.00~3.00%), it outperforms standard stainless steel grades in resisting acidic, alkaline, and chloride-containing media. The forging process further optimizes its tensile strength, elongation, and hardness, making the Forging Tube Sheet suitable for high-temperature, high-pressure, and corrosion-prone applications. Additionally, its compliance with food and pharmaceutical hygiene standards makes it a trusted choice for hygiene-critical industries.

Item | Specification |

Material | SUS316L Stainless Steel (Forged) |

Chemical Composition | C≤0.03%, Si≤1.00%, Mn≤2.00%, P≤0.045%, S≤0.030%, Cr:16.00~18.00%, Ni:10.00~14.00%, Mo:2.00~3.00% |

Mechanical Properties | Tensile Strength (σb): ≥480MPa; Yield Strength (σ0.2): ≥177MPa; Elongation (δ5): ≥40%; Hardness: ≤187HB |

Maximum Diameter | Up to 2000mm |

Heat Treatment | Solution treatment (1010-1150℃) + rapid water cooling |

Delivery Conditions | 1. Forged + annealing + black surface; 2. Forged + annealing + turning; 3. Forged + solution + black surface; 4. Forged + solution + turning; 5. Forged + solution + turning + drilling |

Brand | ETERNAL |

Model | FORGE-TS |

Precision Forging Craftsmanship: Ensures uniform grain structure, high structural integrity, and no internal porosity, enhancing the Stainless Steel Tube Sheet’s service life.

Superior SUS316L Material: Delivers exceptional corrosion resistance, ideal for harsh media in chemical and metallurgical industries.

Excellent High-Temperature Stability: Withstands extreme temperatures, making it perfect for Heat Exchanger Tube Sheet applications in high-heat environments.

Strict Dimension Control: Max diameter up to 2000mm, with precise tolerances to fit custom equipment requirements.

Versatile Delivery Options: Multiple processing states (drilled, turned, black surface) to match diverse installation needs.

Food & Pharma Compliance: Meets international hygiene standards, safe for contact with food and pharmaceutical products.

Easy Cleaning & Maintenance: Smooth surface finish reduces residue buildup, simplifying routine upkeep.

Strong Mechanical Performance: High tensile strength and elongation rate ensure resistance to deformation under heavy loads.

Used in metallurgical step heating furnaces to recover high-temperature flue gas waste heat, preheat combustion air or gas, and improve furnace thermal efficiency. The corrosion-resistant tube sheet copes with acidic/alkaline media in metallurgical processes, extending equipment lifespan.

Integral to stainless steel tube heat exchangers for heating, cooling, condensation, and evaporation. Suitable for circulating water systems in chemistry, electronics, electroplating, semiconductors, and cooling towers—resisting corrosive chemicals and high pressure.

Applied in processing lines for milk, juice, beer, and other beverages. The hygienic SUS316L tube sheet ensures product safety, is easy to sanitize, and maintains consistent heating/cooling performance.

Critical for heat exchange in drug synthesis and formulation. Its corrosion resistance and high-temperature stability prevent contamination, adhering to strict pharmaceutical production standards.

SUS316L contains molybdenum, offering superior corrosion resistance against acids, alkalis, and chlorides—ideal for harsh industrial and hygiene-critical applications. It also has lower carbon content, reducing the risk of intergranular corrosion after heat treatment.

We supply Forged SUS316L Stainless Steel Tube Sheets with a maximum diameter of 2000mm, customizable to smaller sizes based on your equipment needs.

Solution treatment (heating to 1010-1150℃ and rapid cooling) dissolves precipitated carbides, homogenizes the material structure, and restores optimal corrosion resistance and mechanical properties.

Yes—its forging process and excellent mechanical properties (tensile strength ≥480MPa) make it suitable for high-pressure applications like chemical heat exchangers and industrial boilers.

We recommend “Forged + solution + turning + drilling”—the turned and drilled surface is smooth, easy to clean, and meets food hygiene requirements, avoiding residue buildup.

Absolutely. Our SUS316L Tube Sheet meets ASTM, DIN, and ISO standards, ensuring compatibility with global industrial equipment and compliance with food/pharmaceutical safety regulations.

A Forged SUS316L Stainless Steel Tube Sheet is a high-performance industrial spare part crafted from top-grade SUS316L stainless steel via precision forging technology. Unlike cast tube sheets, the forging process enhances the material’s structural density, eliminating internal defects and significantly boosting its mechanical strength and corrosion resistance. This product is engineered to meet the rigorous demands of harsh industrial environments, where reliability, durability, and hygiene are non-negotiable.

The SUS316L stainless steel base material is the key to its superiority—infused with molybdenum (2.00~3.00%), it outperforms standard stainless steel grades in resisting acidic, alkaline, and chloride-containing media. The forging process further optimizes its tensile strength, elongation, and hardness, making the Forging Tube Sheet suitable for high-temperature, high-pressure, and corrosion-prone applications. Additionally, its compliance with food and pharmaceutical hygiene standards makes it a trusted choice for hygiene-critical industries.

Item | Specification |

Material | SUS316L Stainless Steel (Forged) |

Chemical Composition | C≤0.03%, Si≤1.00%, Mn≤2.00%, P≤0.045%, S≤0.030%, Cr:16.00~18.00%, Ni:10.00~14.00%, Mo:2.00~3.00% |

Mechanical Properties | Tensile Strength (σb): ≥480MPa; Yield Strength (σ0.2): ≥177MPa; Elongation (δ5): ≥40%; Hardness: ≤187HB |

Maximum Diameter | Up to 2000mm |

Heat Treatment | Solution treatment (1010-1150℃) + rapid water cooling |

Delivery Conditions | 1. Forged + annealing + black surface; 2. Forged + annealing + turning; 3. Forged + solution + black surface; 4. Forged + solution + turning; 5. Forged + solution + turning + drilling |

Brand | ETERNAL |

Model | FORGE-TS |

Precision Forging Craftsmanship: Ensures uniform grain structure, high structural integrity, and no internal porosity, enhancing the Stainless Steel Tube Sheet’s service life.

Superior SUS316L Material: Delivers exceptional corrosion resistance, ideal for harsh media in chemical and metallurgical industries.

Excellent High-Temperature Stability: Withstands extreme temperatures, making it perfect for Heat Exchanger Tube Sheet applications in high-heat environments.

Strict Dimension Control: Max diameter up to 2000mm, with precise tolerances to fit custom equipment requirements.

Versatile Delivery Options: Multiple processing states (drilled, turned, black surface) to match diverse installation needs.

Food & Pharma Compliance: Meets international hygiene standards, safe for contact with food and pharmaceutical products.

Easy Cleaning & Maintenance: Smooth surface finish reduces residue buildup, simplifying routine upkeep.

Strong Mechanical Performance: High tensile strength and elongation rate ensure resistance to deformation under heavy loads.

Used in metallurgical step heating furnaces to recover high-temperature flue gas waste heat, preheat combustion air or gas, and improve furnace thermal efficiency. The corrosion-resistant tube sheet copes with acidic/alkaline media in metallurgical processes, extending equipment lifespan.

Integral to stainless steel tube heat exchangers for heating, cooling, condensation, and evaporation. Suitable for circulating water systems in chemistry, electronics, electroplating, semiconductors, and cooling towers—resisting corrosive chemicals and high pressure.

Applied in processing lines for milk, juice, beer, and other beverages. The hygienic SUS316L tube sheet ensures product safety, is easy to sanitize, and maintains consistent heating/cooling performance.

Critical for heat exchange in drug synthesis and formulation. Its corrosion resistance and high-temperature stability prevent contamination, adhering to strict pharmaceutical production standards.

SUS316L contains molybdenum, offering superior corrosion resistance against acids, alkalis, and chlorides—ideal for harsh industrial and hygiene-critical applications. It also has lower carbon content, reducing the risk of intergranular corrosion after heat treatment.

We supply Forged SUS316L Stainless Steel Tube Sheets with a maximum diameter of 2000mm, customizable to smaller sizes based on your equipment needs.

Solution treatment (heating to 1010-1150℃ and rapid cooling) dissolves precipitated carbides, homogenizes the material structure, and restores optimal corrosion resistance and mechanical properties.

Yes—its forging process and excellent mechanical properties (tensile strength ≥480MPa) make it suitable for high-pressure applications like chemical heat exchangers and industrial boilers.

We recommend “Forged + solution + turning + drilling”—the turned and drilled surface is smooth, easy to clean, and meets food hygiene requirements, avoiding residue buildup.

Absolutely. Our SUS316L Tube Sheet meets ASTM, DIN, and ISO standards, ensuring compatibility with global industrial equipment and compliance with food/pharmaceutical safety regulations.