| Availability: | |

|---|---|

| Quantity: | |

FORGE -V

ETERNAL

F316L Stainless Steel Feature

F316L is a low-carbon 316 stainless steel, belonging to the austenitic stainless steel series. Its core characteristics revolve around good corrosion resistance, optimized welding performance, and excellent comprehensive mechanical properties, as follows:

Excellent corrosion resistance

The basic components include chromium (Cr), nickel (Ni), and molybdenum (Mo). Molybdenum can significantly improve the resistance to pitting and crevice corrosion in chloride media, and is suitable for corrosive environments such as seawater and chemical solutions.

Good welding performance

Low carbon content is the key to its excellent welding performance. It can maintain good corrosion resistance and mechanical properties without the need for solution treatment after welding, making it suitable for manufacturing large equipment or components that require welding.

Excellent mechanical and process performance

At room temperature, it has high strength and plasticity, good elongation, and can be formed by various cold working methods such as stamping, bending, and stretching. Meanwhile, it has good heat resistance and can maintain stable performance at temperatures ≤ 800 ℃. It is also less prone to brittle fracture in low-temperature environments.

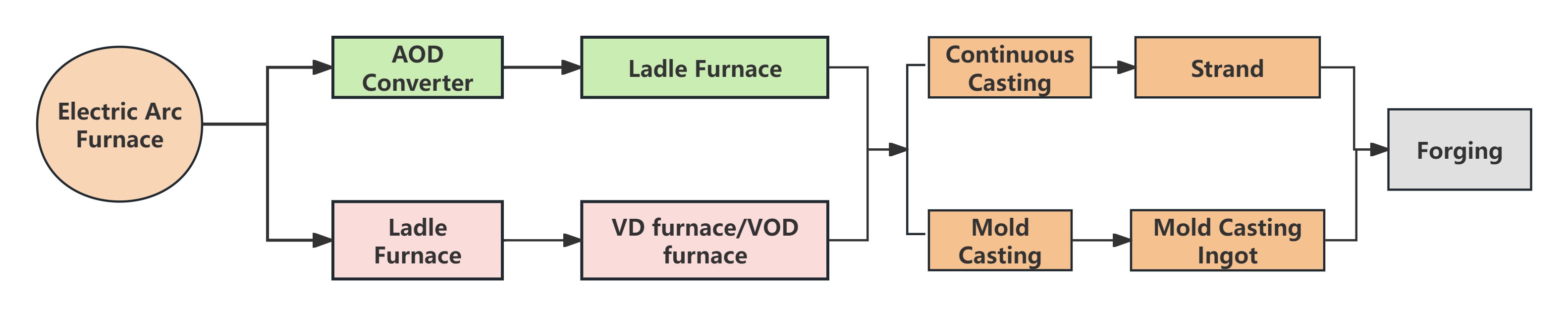

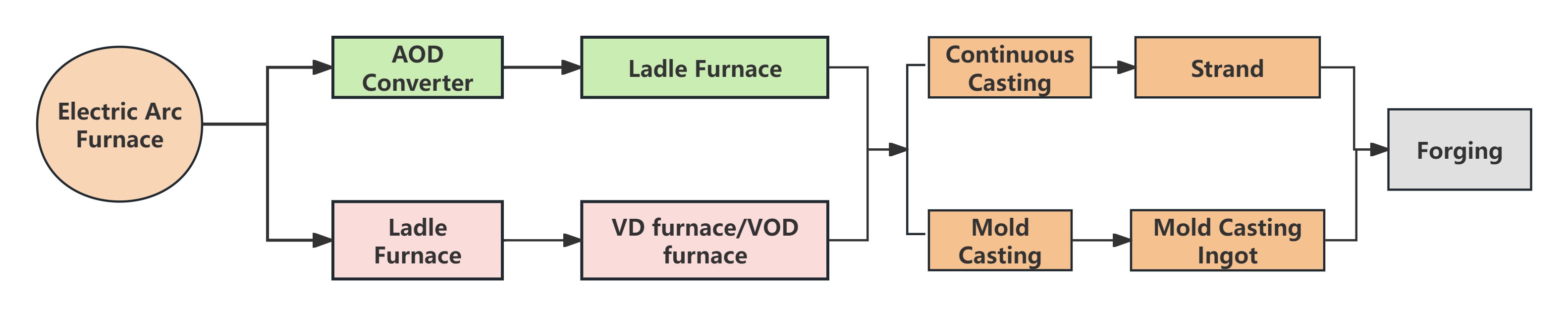

Production Procedure

F316L Chemical Composition

| Steel Grade | Standard | Chemical Composition(%) | ||||||||

| C | Si | Mn | P | S | Cr | Mo | Ni | N | ||

| F316L | ASME SA182-2025 ASTM A182-24 | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 16.0-18.0 | 2.00-3.00 | 10.0-15.0 | ≤0.10 |

F316L Mechanical Property

| Steel Grade | Standard | tensile strength Rm MPa | Yield Strength MPa | Elongation A5 % | Reduction of area Z% | ||

| Rp0.2 | L | Tr | L | Tr | |||

| F316L | ASME SA182-2025 ASTM A182-24 | ≥485 | ≥170 | ≥30 | ≥30 | ≥50 | ≥50 |

| ≥450 | ≥170 | ≥30 | ≥30 | ≥50 | ≥50 | ||

F316L Heat Treatment

The heat treatment of F316L stainless steel mainly revolves around solid solution treatment (to improve corrosion resistance and restore plasticity) and stress relief heat treatment (to avoid stress cracking after processing or welding).

1、 Core heat treatment process: solid solution treatment

Process parameters

Heating temperature: commonly 1050-1100 ℃. If the temperature is too high, it can lead to coarse grains, while if it is too low, the alloy elements cannot be fully dissolved.

Insulation time: determined according to the thickness of the workpiece, generally 1-2 hours/25mm thickness, to ensure uniform heating of the entire workpiece.

Cooling method: rapid water cooling (preferred) or forced air cooling, the core is to ensure that the cooling rate is fast enough to suppress the precipitation of carbides (such as Cr ₂ ∝ C ₆) at grain boundaries.

2、 Auxiliary heat treatment process: stress relief heat treatment

F316L will generate internal stress after cold processing (such as cold drawing, cold stamping) and welding. If directly used in a corrosive environment, it is prone to stress corrosion cracking (SCC), so stress relief heat treatment is required.

Process parameters

Heating temperature: 500~900 ℃

Insulation time: Generally 2-4 hours depending on the size of the workpiece and stress distribution.

Cooling method: Air cooling or water cooling are both acceptable.

Processing purpose:

1.Eliminate residual internal stresses generated by cold processing or welding (which can eliminate over 80% of residual stresses) and reduce the risk of stress corrosion cracking.

2.Slight recovery of plasticity after cold processing does not affect the corrosion resistance of the material.

Applicable scenarios

1.Welded pressure vessels, pipelines, valves, and other components.

2.Precision parts that have undergone deep drawing and cold drawing, such as medical devices and food grade pipe fittings.

F316L Valve Body Application

Petrochemical industry: F316L forged valve body can be used in the production, storage, and transportation of petroleum and chemical products, such as inlet and outlet valves for crude oil pipelines and chemical raw material storage tanks, which can reliably control the flow of various corrosive media.

Natural gas industry: F316L forged valve bodies have also been widely used in the extraction, purification, transportation, and liquefaction of natural gas. For example, in LNG (liquefied natural gas) receiving stations, valves used for low-temperature media often use F316L forged valve bodies to ensure normal operation in a low-temperature environment of -196 ℃.

Pharmaceutical industry: The pharmaceutical industry has extremely high requirements for hygiene and corrosion resistance. F316L forged valve body, due to its excellent corrosion resistance and hygiene performance, can be used for various fluid controls in pharmaceutical processes, such as valves for raw material transportation, liquid filling and other links in drug production.

Representative product

F316L forged ball valve: usually adopts floating ball or fixed ball structure, with good sealing performance and flow capacity, suitable for cutting off or connecting media in pipelines, widely used in low-temperature liquid transportation, chemical fluid control and other fields.

F316L forged gate valve: The valve plate of the gate valve moves up and down along the direction perpendicular to the flow of the medium, and can achieve full open or full close function. It has the characteristics of low flow resistance and reliable sealing, and is commonly used in large-diameter pipelines in industries such as petroleum, chemical, and power.

F316L forged check valve: Check valves can prevent medium backflow and protect equipment and pipeline safety. F316L forged check valve can be used in industries such as chemical, food and beverage. Its forging process ensures the strength and sealing performance of the valve body, effectively preventing the reverse flow of the medium.

F316L Stainless Steel Feature

F316L is a low-carbon 316 stainless steel, belonging to the austenitic stainless steel series. Its core characteristics revolve around good corrosion resistance, optimized welding performance, and excellent comprehensive mechanical properties, as follows:

Excellent corrosion resistance

The basic components include chromium (Cr), nickel (Ni), and molybdenum (Mo). Molybdenum can significantly improve the resistance to pitting and crevice corrosion in chloride media, and is suitable for corrosive environments such as seawater and chemical solutions.

Good welding performance

Low carbon content is the key to its excellent welding performance. It can maintain good corrosion resistance and mechanical properties without the need for solution treatment after welding, making it suitable for manufacturing large equipment or components that require welding.

Excellent mechanical and process performance

At room temperature, it has high strength and plasticity, good elongation, and can be formed by various cold working methods such as stamping, bending, and stretching. Meanwhile, it has good heat resistance and can maintain stable performance at temperatures ≤ 800 ℃. It is also less prone to brittle fracture in low-temperature environments.

Production Procedure

F316L Chemical Composition

| Steel Grade | Standard | Chemical Composition(%) | ||||||||

| C | Si | Mn | P | S | Cr | Mo | Ni | N | ||

| F316L | ASME SA182-2025 ASTM A182-24 | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 16.0-18.0 | 2.00-3.00 | 10.0-15.0 | ≤0.10 |

F316L Mechanical Property

| Steel Grade | Standard | tensile strength Rm MPa | Yield Strength MPa | Elongation A5 % | Reduction of area Z% | ||

| Rp0.2 | L | Tr | L | Tr | |||

| F316L | ASME SA182-2025 ASTM A182-24 | ≥485 | ≥170 | ≥30 | ≥30 | ≥50 | ≥50 |

| ≥450 | ≥170 | ≥30 | ≥30 | ≥50 | ≥50 | ||

F316L Heat Treatment

The heat treatment of F316L stainless steel mainly revolves around solid solution treatment (to improve corrosion resistance and restore plasticity) and stress relief heat treatment (to avoid stress cracking after processing or welding).

1、 Core heat treatment process: solid solution treatment

Process parameters

Heating temperature: commonly 1050-1100 ℃. If the temperature is too high, it can lead to coarse grains, while if it is too low, the alloy elements cannot be fully dissolved.

Insulation time: determined according to the thickness of the workpiece, generally 1-2 hours/25mm thickness, to ensure uniform heating of the entire workpiece.

Cooling method: rapid water cooling (preferred) or forced air cooling, the core is to ensure that the cooling rate is fast enough to suppress the precipitation of carbides (such as Cr ₂ ∝ C ₆) at grain boundaries.

2、 Auxiliary heat treatment process: stress relief heat treatment

F316L will generate internal stress after cold processing (such as cold drawing, cold stamping) and welding. If directly used in a corrosive environment, it is prone to stress corrosion cracking (SCC), so stress relief heat treatment is required.

Process parameters

Heating temperature: 500~900 ℃

Insulation time: Generally 2-4 hours depending on the size of the workpiece and stress distribution.

Cooling method: Air cooling or water cooling are both acceptable.

Processing purpose:

1.Eliminate residual internal stresses generated by cold processing or welding (which can eliminate over 80% of residual stresses) and reduce the risk of stress corrosion cracking.

2.Slight recovery of plasticity after cold processing does not affect the corrosion resistance of the material.

Applicable scenarios

1.Welded pressure vessels, pipelines, valves, and other components.

2.Precision parts that have undergone deep drawing and cold drawing, such as medical devices and food grade pipe fittings.

F316L Valve Body Application

Petrochemical industry: F316L forged valve body can be used in the production, storage, and transportation of petroleum and chemical products, such as inlet and outlet valves for crude oil pipelines and chemical raw material storage tanks, which can reliably control the flow of various corrosive media.

Natural gas industry: F316L forged valve bodies have also been widely used in the extraction, purification, transportation, and liquefaction of natural gas. For example, in LNG (liquefied natural gas) receiving stations, valves used for low-temperature media often use F316L forged valve bodies to ensure normal operation in a low-temperature environment of -196 ℃.

Pharmaceutical industry: The pharmaceutical industry has extremely high requirements for hygiene and corrosion resistance. F316L forged valve body, due to its excellent corrosion resistance and hygiene performance, can be used for various fluid controls in pharmaceutical processes, such as valves for raw material transportation, liquid filling and other links in drug production.

Representative product

F316L forged ball valve: usually adopts floating ball or fixed ball structure, with good sealing performance and flow capacity, suitable for cutting off or connecting media in pipelines, widely used in low-temperature liquid transportation, chemical fluid control and other fields.

F316L forged gate valve: The valve plate of the gate valve moves up and down along the direction perpendicular to the flow of the medium, and can achieve full open or full close function. It has the characteristics of low flow resistance and reliable sealing, and is commonly used in large-diameter pipelines in industries such as petroleum, chemical, and power.

F316L forged check valve: Check valves can prevent medium backflow and protect equipment and pipeline safety. F316L forged check valve can be used in industries such as chemical, food and beverage. Its forging process ensures the strength and sealing performance of the valve body, effectively preventing the reverse flow of the medium.