| Availability: | |

|---|---|

| Quantity: | |

FORGE -DS

ETERNAL

The S32750 duplex stainless steel bushing is a mechanical component made of S32750 duplex stainless steel material, commonly used in applications requiring high strength and high corrosion resistance.

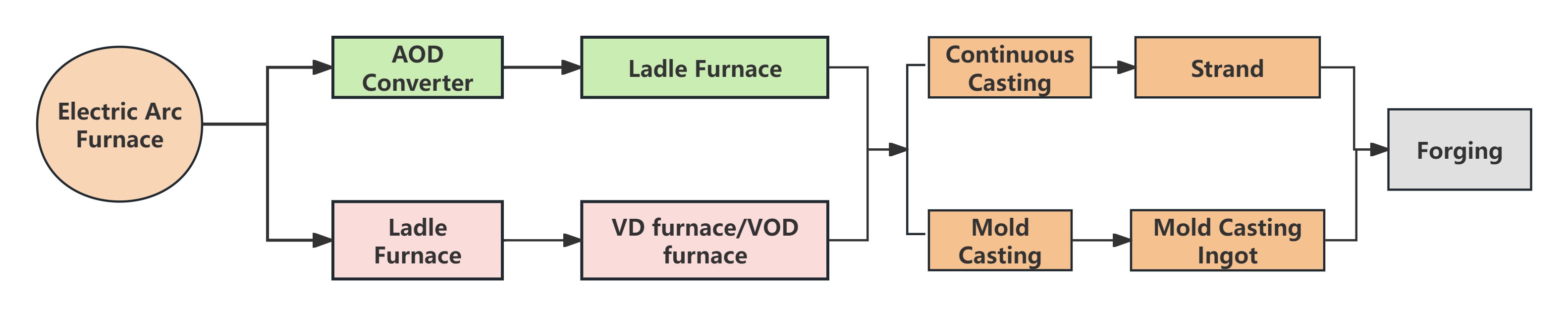

Production Procedure

S32750 and Other Similar Duplex Stainless Steel Material Steel Grade

GB/T | UNS | AISI/ASTM | ID | Trademark | JIS | W.Nr | |

Duplex Stainless Steel | 022Cr22Ni5Mo3N | S31803 | F51 | AL2205 | SUS32953L | 1.4462 | |

OCr26Ni5Mo2 | S32900 | 329 | SUS32951 | 1.446 | |||

S32950 | F52 | ||||||

022Cr25Ni7Mo4N | S32750 | 2507 | F53 | 1.441 | |||

S39274 | F54 | ||||||

022Cr25Ni7Mo4WCuN | S32760 | F55 | 1.4501 | ||||

022Cr23Ni5Mo3N | S32205 | 2205 | F60 | ||||

03Cr25Ni6Mo#Cu2N | S32550 | 255 | F61 | SUS32954L | 1.4507 |

S32750 Chemical Composition

| C | Si | Mn | Cr | Mo | N | Ni | Cu | P | S |

| ≤0.03% | ≤0.8% | ≤1.2% | 24-26% | 3-5% | 0.24-0.32% | 6-8% | ≤0.5% | ≤0.035% | ≤0.02% |

Mechanical Property

The core mechanical properties of S32750 duplex stainless steel bushings are characterized by high strength and high toughness.

Strong and balanced: It combines the high strength of ferritic stainless steel with the excellent toughness of austenitic stainless steel, avoiding the performance shortcomings of single-phase stainless steel.

Good stability: Within the operating temperature range of -20℃ to 300℃, the mechanical properties exhibit minimal fluctuation and can maintain stability over a long period of time.

Fatigue resistance: Excellent resistance to corrosion fatigue and stress fatigue, suitable for cyclic load conditions.

Core mechanical performance parameters (in solution annealed state):

Tensile strength: ≥750MPa, significantly higher than ordinary stainless steel, with stronger load-bearing capacity.

Yield strength: ≥550MPa, excellent resistance to deformation, suitable for high-pressure conditions.

Elongation: ≥25%, good toughness, capable of withstanding certain impacts and deformations.

Hardness: HB≤290 (or HRC≤30), combining strength and machinability.

Impact energy: ≥47J (at -20℃), excellent low-temperature toughness, strong impact resistance.

The processing and welding of S32750 require special attention to the following points:

Heat treatment: The solution treatment temperature is 1020-1100 ℃, and rapid water quenching is used to optimize the biphasic ratio; After forging, it is necessary to immediately cool it with water to avoid the precipitation of brittle phases

Welding: It is recommended to use ER2594 or ERNiCrMo-3 welding materials with interlayer temperature ≤ 100 ℃. No heat treatment is required after welding, but carbon steel contamination should be avoided

Forming processing: The forging temperature is 1000-1180 ℃, and the final forging temperature needs to be controlled between 800-900 ℃

Application

Marine engineering: It can be used in seawater desalination equipment, pipeline systems for offshore platforms, etc., and is resistant to corrosion from chlorides in seawater.

Oil and gas industry: It is suitable for pipelines, valves, etc. in acidic oil and gas wells containing hydrogen sulfide, carbon dioxide, and chloride, as well as subsea oil and gas transmission pipelines.

Chemical industry: It can be used for reactors, storage tanks, and pipelines in the production of sulfuric acid, hydrochloric acid, and other chemical equipment. It is also widely used in chemical processes involving chlorides.

Energy industry: It is commonly used in pipelines and heat exchangers for flue gas desulfurization systems, as well as corrosion-resistant heat exchangers and pipeline systems in nuclear power and traditional power plants.

The S32750 duplex stainless steel bushing is a mechanical component made of S32750 duplex stainless steel material, commonly used in applications requiring high strength and high corrosion resistance.

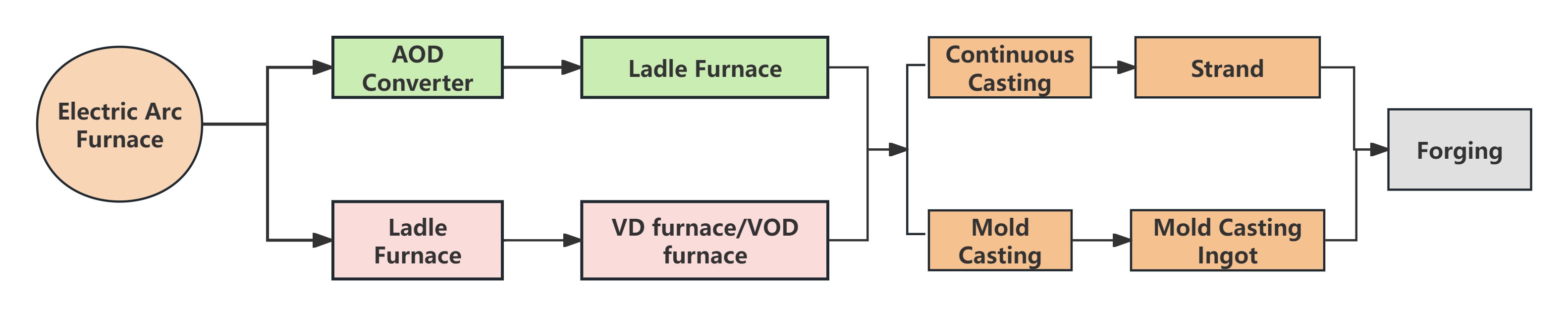

Production Procedure

S32750 and Other Similar Duplex Stainless Steel Material Steel Grade

GB/T | UNS | AISI/ASTM | ID | Trademark | JIS | W.Nr | |

Duplex Stainless Steel | 022Cr22Ni5Mo3N | S31803 | F51 | AL2205 | SUS32953L | 1.4462 | |

OCr26Ni5Mo2 | S32900 | 329 | SUS32951 | 1.446 | |||

S32950 | F52 | ||||||

022Cr25Ni7Mo4N | S32750 | 2507 | F53 | 1.441 | |||

S39274 | F54 | ||||||

022Cr25Ni7Mo4WCuN | S32760 | F55 | 1.4501 | ||||

022Cr23Ni5Mo3N | S32205 | 2205 | F60 | ||||

03Cr25Ni6Mo#Cu2N | S32550 | 255 | F61 | SUS32954L | 1.4507 |

S32750 Chemical Composition

| C | Si | Mn | Cr | Mo | N | Ni | Cu | P | S |

| ≤0.03% | ≤0.8% | ≤1.2% | 24-26% | 3-5% | 0.24-0.32% | 6-8% | ≤0.5% | ≤0.035% | ≤0.02% |

Mechanical Property

The core mechanical properties of S32750 duplex stainless steel bushings are characterized by high strength and high toughness.

Strong and balanced: It combines the high strength of ferritic stainless steel with the excellent toughness of austenitic stainless steel, avoiding the performance shortcomings of single-phase stainless steel.

Good stability: Within the operating temperature range of -20℃ to 300℃, the mechanical properties exhibit minimal fluctuation and can maintain stability over a long period of time.

Fatigue resistance: Excellent resistance to corrosion fatigue and stress fatigue, suitable for cyclic load conditions.

Core mechanical performance parameters (in solution annealed state):

Tensile strength: ≥750MPa, significantly higher than ordinary stainless steel, with stronger load-bearing capacity.

Yield strength: ≥550MPa, excellent resistance to deformation, suitable for high-pressure conditions.

Elongation: ≥25%, good toughness, capable of withstanding certain impacts and deformations.

Hardness: HB≤290 (or HRC≤30), combining strength and machinability.

Impact energy: ≥47J (at -20℃), excellent low-temperature toughness, strong impact resistance.

The processing and welding of S32750 require special attention to the following points:

Heat treatment: The solution treatment temperature is 1020-1100 ℃, and rapid water quenching is used to optimize the biphasic ratio; After forging, it is necessary to immediately cool it with water to avoid the precipitation of brittle phases

Welding: It is recommended to use ER2594 or ERNiCrMo-3 welding materials with interlayer temperature ≤ 100 ℃. No heat treatment is required after welding, but carbon steel contamination should be avoided

Forming processing: The forging temperature is 1000-1180 ℃, and the final forging temperature needs to be controlled between 800-900 ℃

Application

Marine engineering: It can be used in seawater desalination equipment, pipeline systems for offshore platforms, etc., and is resistant to corrosion from chlorides in seawater.

Oil and gas industry: It is suitable for pipelines, valves, etc. in acidic oil and gas wells containing hydrogen sulfide, carbon dioxide, and chloride, as well as subsea oil and gas transmission pipelines.

Chemical industry: It can be used for reactors, storage tanks, and pipelines in the production of sulfuric acid, hydrochloric acid, and other chemical equipment. It is also widely used in chemical processes involving chlorides.

Energy industry: It is commonly used in pipelines and heat exchangers for flue gas desulfurization systems, as well as corrosion-resistant heat exchangers and pipeline systems in nuclear power and traditional power plants.