| Availability: | |

|---|---|

| Quantity: | |

FORGE-BLOCK

ETERNAL

H13 (4Cr5MoSiV1) is the most widely used hot work die steel, with core advantages including high hardenability, high toughness, excellent resistance to hot cracking and thermal fatigue, minimal heat treatment deformation, and comprehensive adaptability to hot work conditions.

H13 Chemical Composition

| C | Si | Mn | Cr | Mo | V | P/S |

| 0.32-0.45% | 0.8-1.2% | 0.2-0.5% | 4.75-5.5% | 1.1-1.75% | 0.8-1.2% | ≤0.03% |

Heat treatment

The core objective of heat treatment for H13 die steel is to achieve high toughness, high thermal fatigue resistance, and stable hardness, in order to adapt to the working conditions of hot work dies. The heat treatment process mainly includes preheating, quenching, tempering, and in some cases, surface strengthening treatment.

Preheat treatment (annealing)

The purpose is to reduce the hardness of steel, eliminate forging stress, improve machinability, and prepare the microstructure for subsequent quenching.

process parameters

Heating temperature: 850-880℃

Holding time: calculated based on the effective thickness of steel, generally 2-4min/mm

Cooling method: Slowly cool down to below 500℃ with the furnace, then remove from the furnace and allow to air cool

Condition after annealing

Hardness: 185-235HBW

Metallographic structure: spheroidal pearlite + uniformly distributed carbides

Quenching treatment (core strengthening step)

The purpose of quenching is to obtain a supersaturated austenite structure in steel, laying the foundation for the matching of strength and toughness after tempering. H13 steel has good hardenability, and uniform quenching can be achieved even for large-section molds.

Key process points

Preheating in two stages: To prevent mold cracking and reduce deformation, it is necessary to preheat in two stages

①Low-temperature preheating: 550-600℃, holding time 1-2min/mm

② High-temperature preheating: 850-900℃, holding time 1-2min/mm

Quenching heating: Temperature 1020-1050℃ (under conventional conditions), which can be raised to 1060℃ if higher hardness is desired; holding time 1-1.5min/mm

Cooling method: Selected based on mold size and precision requirements

① Oil cooling: suitable for small and medium-sized molds, featuring fast cooling speed and uniform hardness

② Air cooling: suitable for large molds, reducing the risk of deformation and cracking

③ High-pressure gas cooling / graded quenching (isothermal at 200-300℃): suitable for high-precision molds, with minimal deformation

State after quenching

Hardness: 57-62HRC

Metallographic structure: martensite + retained austenite + a small amount of undissolved carbide

Note: After quenching, the mold needs to be tempered promptly to avoid cracking caused by residual stress. The interval should not exceed 4 hours.

Tempering treatment (determining the final performance)

The purpose of tempering is to eliminate residual stress from quenching, reduce brittleness, and adjust the balance between hardness and toughness through carbide precipitation. H13 steel requires multiple tempering processes to fully eliminate residual austenite.

Conventional tempering process (suitable for hot work molds)

Tempering temperature: 580-620℃ (optimal range)

Tempering times: 2 times, with a holding time of 2-3min/mm for each time

Cooling method: air cooling after exiting the furnace

State after tempering

Hardness: 47-49HRC (excellent toughness, suitable for die-casting molds and forging molds)

Metallographic structure: tempered sorbite + uniform carbide

Performance adjustment at different tempering temperatures

| Tempering temperature range | Hardness range | Applicable scenarios |

| 200-300℃ | 55-58HRC | Low-temperature, low-load mold with poor toughness |

| 400-500℃ | 48-52HRC | Hot extrusion die for medium impact load |

| 550-650℃ | 40-48HRC | Die-casting / forging molds with high impact and thermal fatigue resistance |

Surface strengthening treatment

For molds with high wear resistance requirements, surface treatment can be performed after tempering, but it should be noted that this may slightly reduce the resistance to hot cracking:

Gas nitriding: Temperature 520-560℃, holding time 20-50h, surface hardness 65-70HRC, nitriding layer depth 0.3-0.5mm

Nitrocarburizing: Temperature 560-580℃, holding time 2-4h, surface hardness 60-65HRC, achieving both wear resistance and corrosion resistance

Carburizing: Applicable only to low-load molds, with a temperature range of 900-930℃. It significantly enhances surface hardness, but significantly reduces thermal crack resistance

Mechanical Property

The following are typical mechanical property data after standard heat treatment (quenching at 1020-1050℃ + tempering twice at 600℃)

Hardness: 47-49 HRC. This is the typical service hardness range for conventional molds

Tensile strength ≥1500 MPa . Tensile properties at room temperature

Yield strength ≥1200 MPa .

Elongation rate ≥10% . Elongation rate after fracture

Reduction of area ≥40% . Reflect the plasticity of the material

Impact toughness (αk) ≥ 15-20 J/cm². Excellent toughness in unnotched impact tests at room temperature

High-temperature hardness: approximately 40 HRC (500℃),35 HRC (540℃)

Feature

High hardenability and toughness: Chromium, molybdenum, and vanadium optimize hardenability, ensuring uniform hardening of large sections; moderate carbon content combines high toughness and impact resistance, making it suitable for forging and die-casting molds with high impact loads.

Outstanding resistance to thermal cracking and thermal fatigue: It can be temperature-controlled through water cooling during operation, demonstrating strong resistance to cracking caused by cold and heat cycles, and excellent thermal cycle stability.

High temperature softening resistance and thermal strength: It can maintain its hardness stably below 540℃, and still has high strength at 600℃. However, its hardness will rapidly decrease once it exceeds 540℃.

Heat treatment is stable and easily controllable: the quenching and tempering processes are mature, with minimal deformation and easy guarantee of dimensional accuracy; it is recommended to quench at 1020-1050℃ and temper twice at 600℃, achieving a hardness of 47-49HRC.

Flexible processing and surface modification: Moderate to excellent cutting and polishing properties. Surface hardness can be enhanced through carburizing/nitriding, and a combined treatment of nitriding and oxidation can achieve both wear resistance and corrosion resistance.

High comprehensive cost-effectiveness: controllable procurement and heat treatment costs, wide channels, and compatibility with most hot work mold scenarios.

Application

Hot work molds: aluminum/magnesium/zinc alloy die-casting molds, hot extrusion molds, precision forging molds, forging hammer molds, etc.

Mechanical components: aviation high-temperature components, high-stress fixtures, hot shear cutters, etc.

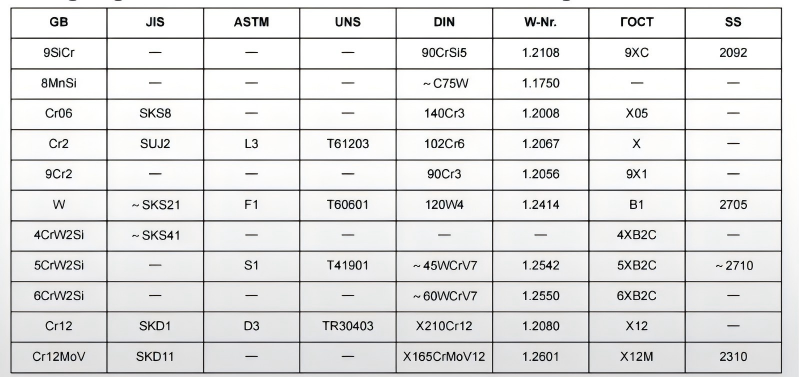

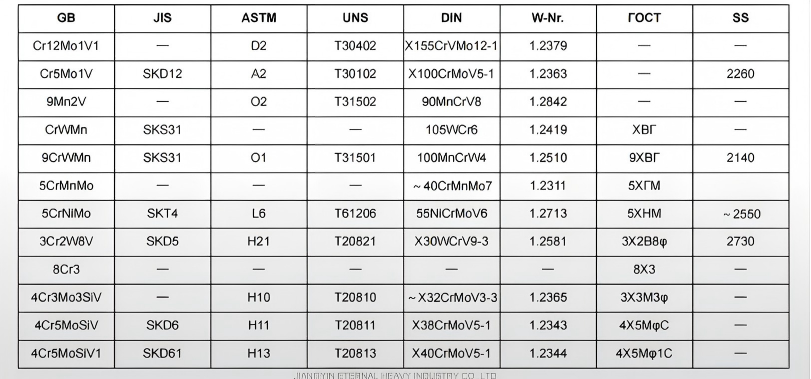

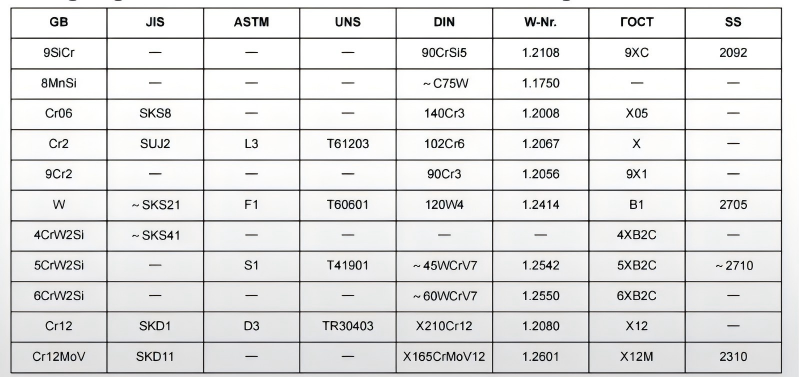

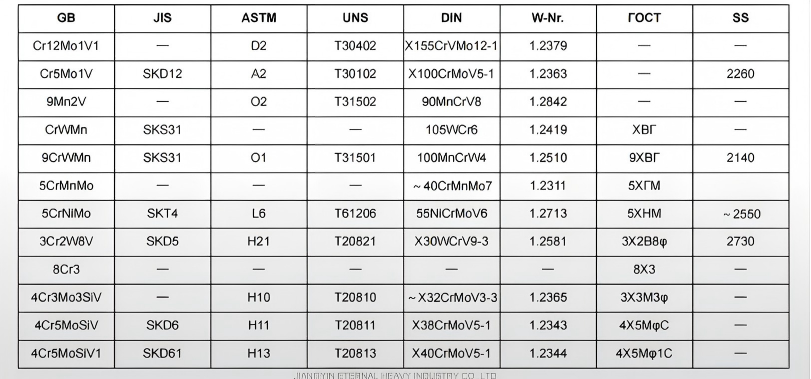

Common Die Steel Steel Grade

H13 (4Cr5MoSiV1) is the most widely used hot work die steel, with core advantages including high hardenability, high toughness, excellent resistance to hot cracking and thermal fatigue, minimal heat treatment deformation, and comprehensive adaptability to hot work conditions.

H13 Chemical Composition

| C | Si | Mn | Cr | Mo | V | P/S |

| 0.32-0.45% | 0.8-1.2% | 0.2-0.5% | 4.75-5.5% | 1.1-1.75% | 0.8-1.2% | ≤0.03% |

Heat treatment

The core objective of heat treatment for H13 die steel is to achieve high toughness, high thermal fatigue resistance, and stable hardness, in order to adapt to the working conditions of hot work dies. The heat treatment process mainly includes preheating, quenching, tempering, and in some cases, surface strengthening treatment.

Preheat treatment (annealing)

The purpose is to reduce the hardness of steel, eliminate forging stress, improve machinability, and prepare the microstructure for subsequent quenching.

process parameters

Heating temperature: 850-880℃

Holding time: calculated based on the effective thickness of steel, generally 2-4min/mm

Cooling method: Slowly cool down to below 500℃ with the furnace, then remove from the furnace and allow to air cool

Condition after annealing

Hardness: 185-235HBW

Metallographic structure: spheroidal pearlite + uniformly distributed carbides

Quenching treatment (core strengthening step)

The purpose of quenching is to obtain a supersaturated austenite structure in steel, laying the foundation for the matching of strength and toughness after tempering. H13 steel has good hardenability, and uniform quenching can be achieved even for large-section molds.

Key process points

Preheating in two stages: To prevent mold cracking and reduce deformation, it is necessary to preheat in two stages

①Low-temperature preheating: 550-600℃, holding time 1-2min/mm

② High-temperature preheating: 850-900℃, holding time 1-2min/mm

Quenching heating: Temperature 1020-1050℃ (under conventional conditions), which can be raised to 1060℃ if higher hardness is desired; holding time 1-1.5min/mm

Cooling method: Selected based on mold size and precision requirements

① Oil cooling: suitable for small and medium-sized molds, featuring fast cooling speed and uniform hardness

② Air cooling: suitable for large molds, reducing the risk of deformation and cracking

③ High-pressure gas cooling / graded quenching (isothermal at 200-300℃): suitable for high-precision molds, with minimal deformation

State after quenching

Hardness: 57-62HRC

Metallographic structure: martensite + retained austenite + a small amount of undissolved carbide

Note: After quenching, the mold needs to be tempered promptly to avoid cracking caused by residual stress. The interval should not exceed 4 hours.

Tempering treatment (determining the final performance)

The purpose of tempering is to eliminate residual stress from quenching, reduce brittleness, and adjust the balance between hardness and toughness through carbide precipitation. H13 steel requires multiple tempering processes to fully eliminate residual austenite.

Conventional tempering process (suitable for hot work molds)

Tempering temperature: 580-620℃ (optimal range)

Tempering times: 2 times, with a holding time of 2-3min/mm for each time

Cooling method: air cooling after exiting the furnace

State after tempering

Hardness: 47-49HRC (excellent toughness, suitable for die-casting molds and forging molds)

Metallographic structure: tempered sorbite + uniform carbide

Performance adjustment at different tempering temperatures

| Tempering temperature range | Hardness range | Applicable scenarios |

| 200-300℃ | 55-58HRC | Low-temperature, low-load mold with poor toughness |

| 400-500℃ | 48-52HRC | Hot extrusion die for medium impact load |

| 550-650℃ | 40-48HRC | Die-casting / forging molds with high impact and thermal fatigue resistance |

Surface strengthening treatment

For molds with high wear resistance requirements, surface treatment can be performed after tempering, but it should be noted that this may slightly reduce the resistance to hot cracking:

Gas nitriding: Temperature 520-560℃, holding time 20-50h, surface hardness 65-70HRC, nitriding layer depth 0.3-0.5mm

Nitrocarburizing: Temperature 560-580℃, holding time 2-4h, surface hardness 60-65HRC, achieving both wear resistance and corrosion resistance

Carburizing: Applicable only to low-load molds, with a temperature range of 900-930℃. It significantly enhances surface hardness, but significantly reduces thermal crack resistance

Mechanical Property

The following are typical mechanical property data after standard heat treatment (quenching at 1020-1050℃ + tempering twice at 600℃)

Hardness: 47-49 HRC. This is the typical service hardness range for conventional molds

Tensile strength ≥1500 MPa . Tensile properties at room temperature

Yield strength ≥1200 MPa .

Elongation rate ≥10% . Elongation rate after fracture

Reduction of area ≥40% . Reflect the plasticity of the material

Impact toughness (αk) ≥ 15-20 J/cm². Excellent toughness in unnotched impact tests at room temperature

High-temperature hardness: approximately 40 HRC (500℃),35 HRC (540℃)

Feature

High hardenability and toughness: Chromium, molybdenum, and vanadium optimize hardenability, ensuring uniform hardening of large sections; moderate carbon content combines high toughness and impact resistance, making it suitable for forging and die-casting molds with high impact loads.

Outstanding resistance to thermal cracking and thermal fatigue: It can be temperature-controlled through water cooling during operation, demonstrating strong resistance to cracking caused by cold and heat cycles, and excellent thermal cycle stability.

High temperature softening resistance and thermal strength: It can maintain its hardness stably below 540℃, and still has high strength at 600℃. However, its hardness will rapidly decrease once it exceeds 540℃.

Heat treatment is stable and easily controllable: the quenching and tempering processes are mature, with minimal deformation and easy guarantee of dimensional accuracy; it is recommended to quench at 1020-1050℃ and temper twice at 600℃, achieving a hardness of 47-49HRC.

Flexible processing and surface modification: Moderate to excellent cutting and polishing properties. Surface hardness can be enhanced through carburizing/nitriding, and a combined treatment of nitriding and oxidation can achieve both wear resistance and corrosion resistance.

High comprehensive cost-effectiveness: controllable procurement and heat treatment costs, wide channels, and compatibility with most hot work mold scenarios.

Application

Hot work molds: aluminum/magnesium/zinc alloy die-casting molds, hot extrusion molds, precision forging molds, forging hammer molds, etc.

Mechanical components: aviation high-temperature components, high-stress fixtures, hot shear cutters, etc.

Common Die Steel Steel Grade