| Availability: | |

|---|---|

| Quantity: | |

FORGE-RB

ETERNAL

Product Description

1. Size: Customized,diameter can reach up to 600mm,and length can reach up to 8000mm.

2. Material: Precipitation Hardening Stainless Steel 17-4

3. Manufacturing method:Forging

4.Heat treatment: Annealing,/Solution/Aging

5. Surface treatment: Polish/Black Surface

6.Shape:Bar /Plate/Flat

7. Warranty period: One year

17-4 PH Chemical Specification

17-4 PH Steel Grade

| Steel Grade | GB/T | JIS | UNS | W-Nr. |

| 17-4 PH | 05Cr17Ni4Cu4Nb | SUS 630 | S17400 | 1.4542 |

Application

It is widely used in the aerospace industry, specifically for manufacturing aircraft structural components and engine parts;

In chemical equipment, it can be used for pump casings, valves, etc;

In the energy industry, it is suitable for key components of oil and gas equipment;

In addition, it can also be used in the medical device field, for manufacturing surgical instruments and implants, etc.

Feature

It possesses high strength and toughness, with a tensile strength reaching 1000-1400MPa. Additionally, its corrosion resistance is comparable to that of 304 stainless steel, and its properties can be adjusted through various heat treatment processes.

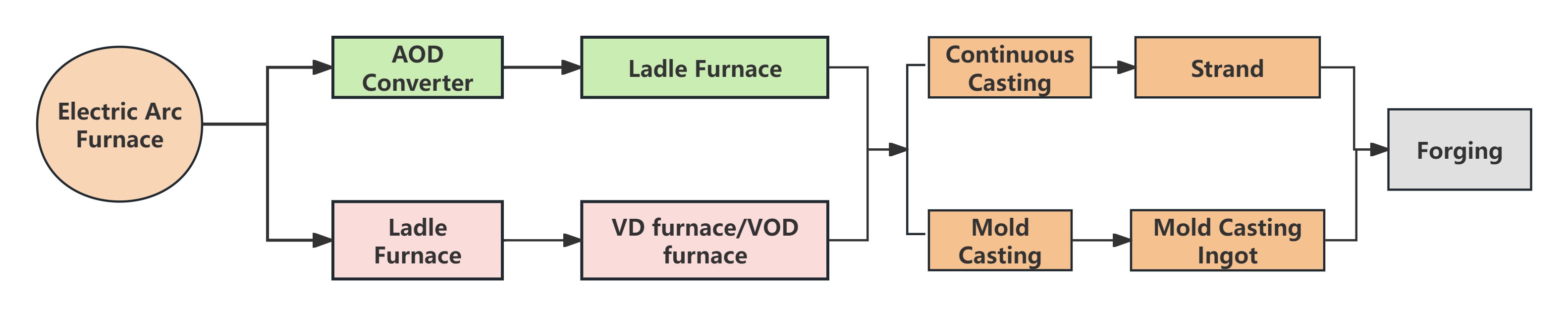

Production Procedure

Mechanical Property and Heat Treatment

Specific mechanical properties under different heat treatment conditions

H900 status (commonly used high-strength status)

1. Tensile strength ≥1310MPa, yield strength ≥1170MPa.

2. The percentage elongation after fracture is ≥10%, and the reduction of area is ≥40%.

3. Hardness: 38~44HRC (or 388~444HBW).

H925 status (balance of strength and toughness)

1. Tensile strength ≥ 1240MPa, yield strength ≥ 1070MPa.

2. The percentage elongation after fracture is ≥12%, and the reduction of area is ≥45%.

3. Hardness: 36~42HRC.

H1025 Status (High Toughness Priority)

1. Tensile strength ≥ 1030 MPa, yield strength ≥ 860 MPa.

2. The percentage elongation after fracture is ≥15%, and the reduction of area is ≥50%.

3. Hardness: 30~36HRC.

H1150 status (ultra-high toughness, low residual stress)

1. Tensile strength ≥ 860MPa, yield strength ≥ 690MPa.

2. The percentage elongation after fracture is ≥18%, and the reduction of area is ≥55%.

3. Hardness: 26~32HRC.

Heat Treatment Process

Heat treatment specifications:

(1) Quick cooling at 1020-1060 ℃ for solid solution;

(2) Aging at 480 ℃, after solid solution treatment, air-cooled at 470-490 ℃;

(3) Aging at 550 ℃, after solid solution treatment, air-cooled at 540-560 ℃;

(4) Aging at 580 ℃, after solid solution treatment, air-cooled at 570-590 ℃;

(5) Aging at 620 ℃, after solid solution treatment, air-cooled at 610-630 ℃.

Metallographic structure: characterized by precipitation hardening.

Delivery condition

Forging + black

Forging + peeled surface

Forging + solution + peeled surface

Forging + solution + aging + peeled surface

Product Description

1. Size: Customized,diameter can reach up to 600mm,and length can reach up to 8000mm.

2. Material: Precipitation Hardening Stainless Steel 17-4

3. Manufacturing method:Forging

4.Heat treatment: Annealing,/Solution/Aging

5. Surface treatment: Polish/Black Surface

6.Shape:Bar /Plate/Flat

7. Warranty period: One year

17-4 PH Chemical Specification

17-4 PH Steel Grade

| Steel Grade | GB/T | JIS | UNS | W-Nr. |

| 17-4 PH | 05Cr17Ni4Cu4Nb | SUS 630 | S17400 | 1.4542 |

Application

It is widely used in the aerospace industry, specifically for manufacturing aircraft structural components and engine parts;

In chemical equipment, it can be used for pump casings, valves, etc;

In the energy industry, it is suitable for key components of oil and gas equipment;

In addition, it can also be used in the medical device field, for manufacturing surgical instruments and implants, etc.

Feature

It possesses high strength and toughness, with a tensile strength reaching 1000-1400MPa. Additionally, its corrosion resistance is comparable to that of 304 stainless steel, and its properties can be adjusted through various heat treatment processes.

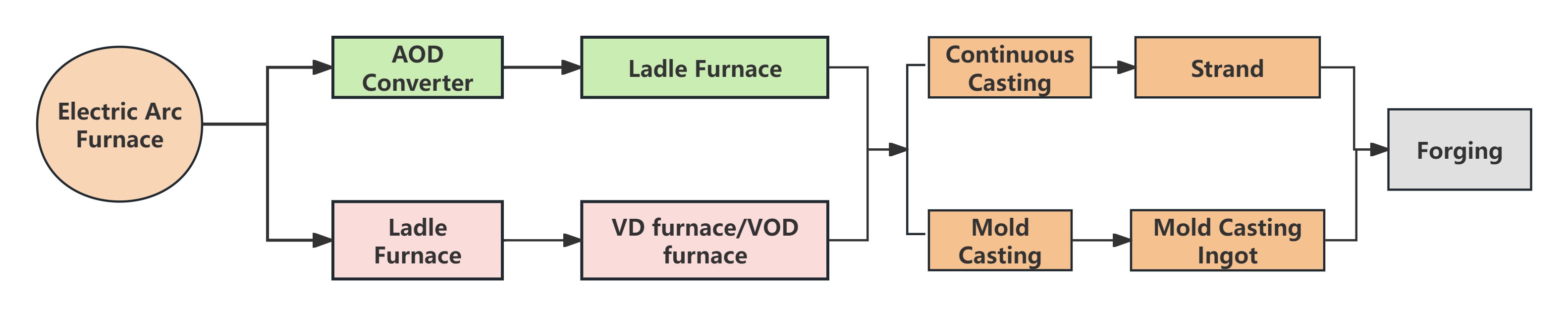

Production Procedure

Mechanical Property and Heat Treatment

Specific mechanical properties under different heat treatment conditions

H900 status (commonly used high-strength status)

1. Tensile strength ≥1310MPa, yield strength ≥1170MPa.

2. The percentage elongation after fracture is ≥10%, and the reduction of area is ≥40%.

3. Hardness: 38~44HRC (or 388~444HBW).

H925 status (balance of strength and toughness)

1. Tensile strength ≥ 1240MPa, yield strength ≥ 1070MPa.

2. The percentage elongation after fracture is ≥12%, and the reduction of area is ≥45%.

3. Hardness: 36~42HRC.

H1025 Status (High Toughness Priority)

1. Tensile strength ≥ 1030 MPa, yield strength ≥ 860 MPa.

2. The percentage elongation after fracture is ≥15%, and the reduction of area is ≥50%.

3. Hardness: 30~36HRC.

H1150 status (ultra-high toughness, low residual stress)

1. Tensile strength ≥ 860MPa, yield strength ≥ 690MPa.

2. The percentage elongation after fracture is ≥18%, and the reduction of area is ≥55%.

3. Hardness: 26~32HRC.

Heat Treatment Process

Heat treatment specifications:

(1) Quick cooling at 1020-1060 ℃ for solid solution;

(2) Aging at 480 ℃, after solid solution treatment, air-cooled at 470-490 ℃;

(3) Aging at 550 ℃, after solid solution treatment, air-cooled at 540-560 ℃;

(4) Aging at 580 ℃, after solid solution treatment, air-cooled at 570-590 ℃;

(5) Aging at 620 ℃, after solid solution treatment, air-cooled at 610-630 ℃.

Metallographic structure: characterized by precipitation hardening.

Delivery condition

Forging + black

Forging + peeled surface

Forging + solution + peeled surface

Forging + solution + aging + peeled surface