| Availability: | |

|---|---|

| Quantity: | |

Customized

ETERNAL

Product Description

1. Size: Customized,diameter can reach up to 600mm,and length can reach up to 8000mm.

2. Material: Precipitation Hardening Stainless Steel 17-7

3. Manufacturing method:Forging

4.Heat treatment: Annealing,/Solution/Aging

5. Surface treatment: Polish/Black Surface

6.Shape:Bar /Plate/Flat

7. Warranty period: One year

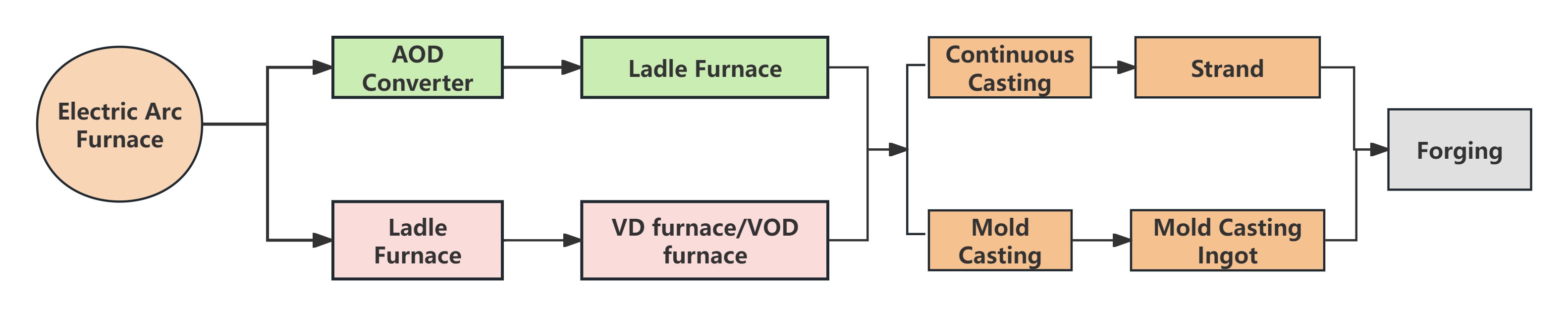

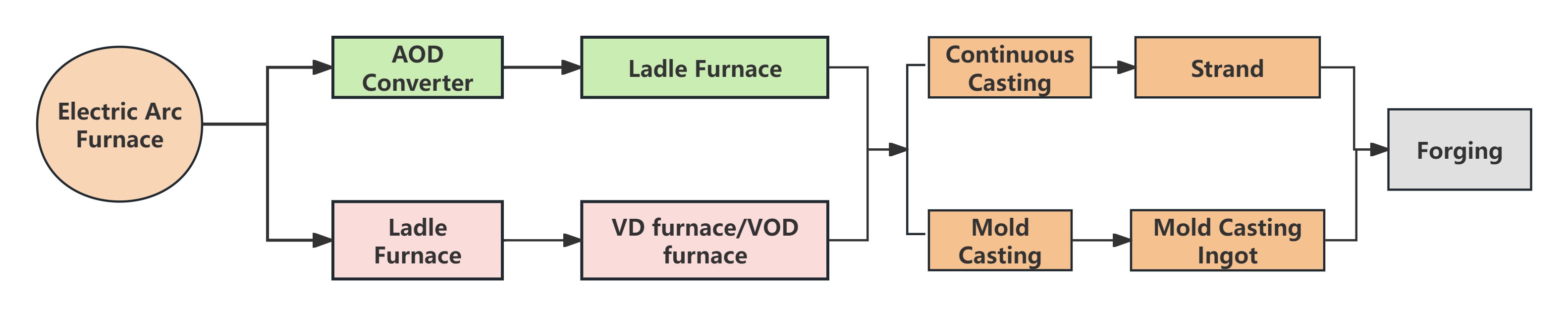

Production Procedure

Application

Aerospace: aircraft structural components, fasteners, instrument panel parts.

Precision manufacturing: medical devices, watch components, electronic equipment casings.

Industrial field: high-pressure valves, springs, and components in low-corrosion environments of chemical equipment.

Feature

17-7PH stainless steel is a precipitation-hardened stainless steel, with its core advantage being its combination of high strength and excellent corrosion resistance, making it

widely used in precision applications.

Composition characteristics: It contains 17% chromium and 7% nickel, and achieves precipitation hardening through elements such as copper and niobium.

Performance advantages: After heat treatment, the strength can reach 1379-1655MPa, far exceeding that of ordinary stainless steel; its corrosion resistance is close to that of 304 stainless steel, capable of withstanding atmospheric conditions, fresh water, and weak corrosive media.

Processing characteristics: Excellent cold workability, suitable for stamping and bending. Good dimensional stability after heat treatment, making it ideal for precision part processing.

17-7 PH Chemical Specification

| C | Si | Mn | Cr | Al | Ni | P | S |

| ≤0.09% | ≤1% | ≤1% | 16-18% | 0.75-1.5% | 6.5-7.75% | ≤0.04% | ≤0.03% |

17-7 PH Steel Grade

| Steel Grade | GB/T | JIS | UNS | W-Nr. |

| 17-7 PH | 07Cr17Ni7Al | SUS 631 | S17700 | 1.4568 |

Mechanical Property and Heat Treatment

Tensile strength: approximately 860-1030 MPa for TH1050 condition, approximately 1380-1550 MPa for CH900 condition, and approximately 1170-1310 MPa for RH950 condition.

Yield strength (0.2% yield): approximately 690-860 MPa for TH1050 condition, approximately 1240-1400 MPa for CH900 condition, and approximately 1030-1170 MPa for RH950 condition.

Elongation (fracture): ≥15% for TH1050 state, ≥6% for CH900 state, and ≥10% for RH950 state.

Hardness (HRC): TH1050 condition is approximately 26-32 HRC, CH900 condition is approximately 42-48 HRC, and RH950 condition is approximately 38-44 HRC

Heat Treatment Process

The core of heat treatment for 17-7 PH stainless steel is "solution treatment + precipitation hardening". Different heat treatment states (TH1050, CH900, RH950) correspond to different processes, ultimately determining its mechanical properties.

Core heat treatment process (general basic steps)

Solution treatment: First, heat the steel to 1000-1050℃ and maintain the temperature for 30-60 minutes.

Rapid cooling: Rapidly reduce the temperature through water quenching or air cooling to obtain a supersaturated austenite structure, preparing for subsequent hardening.

Precipitation hardening (key step): Holding at a specific temperature to promote the precipitation of fine precipitates from alloy elements (such as copper and niobium), thereby enhancing strength.

Specific heat treatment processes for different states

TH1050 condition (solution + stabilization): After solution treatment, cool to room temperature, then heat to 1050℃ and maintain for 30 minutes, followed by air cooling.

CH900 status (high-strength type): After solid solution cooling, heat to 900℃ and maintain for 1 hour, then air cool. Finally, maintain at 480℃ for 4 hours and then air cool.

RH950 status (balanced type): After solid solution cooling, heat to 950℃ and maintain for 1 hour, then air cool. After that, maintain at 510℃ for 4 hours and then air cool.

Delivery condition

1.Forged + annealing + black surface

2.Forged + annealing + polish

3.Forged + solution+aging + black surface

4.Forged + solution+aging + polish

Product Description

1. Size: Customized,diameter can reach up to 600mm,and length can reach up to 8000mm.

2. Material: Precipitation Hardening Stainless Steel 17-7

3. Manufacturing method:Forging

4.Heat treatment: Annealing,/Solution/Aging

5. Surface treatment: Polish/Black Surface

6.Shape:Bar /Plate/Flat

7. Warranty period: One year

Production Procedure

Application

Aerospace: aircraft structural components, fasteners, instrument panel parts.

Precision manufacturing: medical devices, watch components, electronic equipment casings.

Industrial field: high-pressure valves, springs, and components in low-corrosion environments of chemical equipment.

Feature

17-7PH stainless steel is a precipitation-hardened stainless steel, with its core advantage being its combination of high strength and excellent corrosion resistance, making it

widely used in precision applications.

Composition characteristics: It contains 17% chromium and 7% nickel, and achieves precipitation hardening through elements such as copper and niobium.

Performance advantages: After heat treatment, the strength can reach 1379-1655MPa, far exceeding that of ordinary stainless steel; its corrosion resistance is close to that of 304 stainless steel, capable of withstanding atmospheric conditions, fresh water, and weak corrosive media.

Processing characteristics: Excellent cold workability, suitable for stamping and bending. Good dimensional stability after heat treatment, making it ideal for precision part processing.

17-7 PH Chemical Specification

| C | Si | Mn | Cr | Al | Ni | P | S |

| ≤0.09% | ≤1% | ≤1% | 16-18% | 0.75-1.5% | 6.5-7.75% | ≤0.04% | ≤0.03% |

17-7 PH Steel Grade

| Steel Grade | GB/T | JIS | UNS | W-Nr. |

| 17-7 PH | 07Cr17Ni7Al | SUS 631 | S17700 | 1.4568 |

Mechanical Property and Heat Treatment

Tensile strength: approximately 860-1030 MPa for TH1050 condition, approximately 1380-1550 MPa for CH900 condition, and approximately 1170-1310 MPa for RH950 condition.

Yield strength (0.2% yield): approximately 690-860 MPa for TH1050 condition, approximately 1240-1400 MPa for CH900 condition, and approximately 1030-1170 MPa for RH950 condition.

Elongation (fracture): ≥15% for TH1050 state, ≥6% for CH900 state, and ≥10% for RH950 state.

Hardness (HRC): TH1050 condition is approximately 26-32 HRC, CH900 condition is approximately 42-48 HRC, and RH950 condition is approximately 38-44 HRC

Heat Treatment Process

The core of heat treatment for 17-7 PH stainless steel is "solution treatment + precipitation hardening". Different heat treatment states (TH1050, CH900, RH950) correspond to different processes, ultimately determining its mechanical properties.

Core heat treatment process (general basic steps)

Solution treatment: First, heat the steel to 1000-1050℃ and maintain the temperature for 30-60 minutes.

Rapid cooling: Rapidly reduce the temperature through water quenching or air cooling to obtain a supersaturated austenite structure, preparing for subsequent hardening.

Precipitation hardening (key step): Holding at a specific temperature to promote the precipitation of fine precipitates from alloy elements (such as copper and niobium), thereby enhancing strength.

Specific heat treatment processes for different states

TH1050 condition (solution + stabilization): After solution treatment, cool to room temperature, then heat to 1050℃ and maintain for 30 minutes, followed by air cooling.

CH900 status (high-strength type): After solid solution cooling, heat to 900℃ and maintain for 1 hour, then air cool. Finally, maintain at 480℃ for 4 hours and then air cool.

RH950 status (balanced type): After solid solution cooling, heat to 950℃ and maintain for 1 hour, then air cool. After that, maintain at 510℃ for 4 hours and then air cool.

Delivery condition

1.Forged + annealing + black surface

2.Forged + annealing + polish

3.Forged + solution+aging + black surface

4.Forged + solution+aging + polish