| Availability: | |

|---|---|

| Quantity: | |

FORGE-RB

ETERNAL

Product Description

1. Size: Customized,diameter can reach up to 600mm,and length can reach up to 8000mm.

2. Material: Precipitation Hardening Stainless Steel 15-5

3. Manufacturing method:Forging

4.Heat treatment: Annealing/Solution/Aging

5. Surface treatment: Polish/Black Surface

6.Shape:Bar /Plate/Flat

7. Warranty period: One year

15-5 PH Chemical Specification

| C | Si | Mn | Cr | Cu | Ni | Nb | P | S |

| ≤0.07% | ≤1% | ≤1% | 14-15.5% | 2.5-4.5% | 3.5-5.5% | 0.15-0.45% | ≤0.04% | ≤0.03% |

15-5 PH Steel Grade

| Steel Grade | GB/T | UNS | W-Nr. |

| 15-5 PH | 05Cr15Ni5Cu4Nb | XM12 | 1.4545 |

Application

Aerospace: aircraft landing gear parts, engine components, fasteners.

Precision machinery: high-pressure valves, gears, shaft components, and springs.

Others: medical devices, structural components exposed to low chloride ions in marine environments.

Feature

Material properties: Martensitic precipitation hardening stainless steel, combining the corrosion resistance and high strength characteristics of stainless steel.

Mechanical properties: Through solid solution treatment and age hardening, the tensile strength can reach 1000-1380MPa, yield strength 860-1240MPa, elongation ≥ 10%, hardness (HRC) 30-45, and excellent balance of strength and toughness.

Corrosion resistance: superior to ordinary martensitic stainless steel, resistant to atmospheric, freshwater, and neutral salt solution corrosion, with good resistance to slightly corrosive media, suitable for outdoor or humid conditions.

Processing and forging characteristics: The forging temperature range is 1100-1200 ℃, and the hot processing performance is good. It can be forged into complex forgings such as shafts, rollers, and sleeves; After cold processing, it is necessary to promptly perform solution treatment to avoid residual stress.

Stability: After aging treatment, the organization is stable, and good mechanical properties are maintained at high temperatures without obvious aging softening phenomenon, suitable for applications in medium and low temperature conditions.

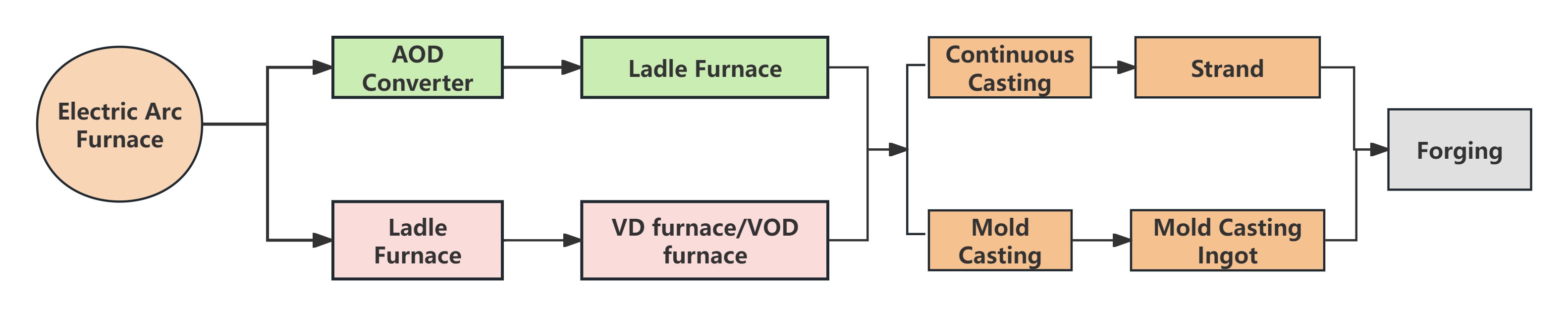

Production Procedure

Mechanical Property and Heat Treatment

The core mechanical properties of 15-5PH stainless steel are high strength and good toughness.

H900 (aging temperature 482℃): yield strength ≥1100MPa, tensile strength ≥1240MPa, elongation ≥10%, hardness ≥38HRC.

H1025 (aging temperature 552℃): yield strength ≥1030MPa, tensile strength ≥1170MPa, elongation ≥12%, hardness ≥35HRC.

H1150 (aging temperature 621℃): yield strength ≥860MPa, tensile strength ≥965MPa, elongation ≥15%, hardness ≥30HRC.

H1150M (aging + stabilization): yield strength ≥790MPa, tensile strength ≥930MPa, elongation ≥18%, superior toughness (impact energy ≥54J).

Delivery condition

Forging + black

Forging + peeled surface

Forging + solution + peeled surface

Forging + solution + aging + peeled surface

Product Description

1. Size: Customized,diameter can reach up to 600mm,and length can reach up to 8000mm.

2. Material: Precipitation Hardening Stainless Steel 15-5

3. Manufacturing method:Forging

4.Heat treatment: Annealing/Solution/Aging

5. Surface treatment: Polish/Black Surface

6.Shape:Bar /Plate/Flat

7. Warranty period: One year

15-5 PH Chemical Specification

| C | Si | Mn | Cr | Cu | Ni | Nb | P | S |

| ≤0.07% | ≤1% | ≤1% | 14-15.5% | 2.5-4.5% | 3.5-5.5% | 0.15-0.45% | ≤0.04% | ≤0.03% |

15-5 PH Steel Grade

| Steel Grade | GB/T | UNS | W-Nr. |

| 15-5 PH | 05Cr15Ni5Cu4Nb | XM12 | 1.4545 |

Application

Aerospace: aircraft landing gear parts, engine components, fasteners.

Precision machinery: high-pressure valves, gears, shaft components, and springs.

Others: medical devices, structural components exposed to low chloride ions in marine environments.

Feature

Material properties: Martensitic precipitation hardening stainless steel, combining the corrosion resistance and high strength characteristics of stainless steel.

Mechanical properties: Through solid solution treatment and age hardening, the tensile strength can reach 1000-1380MPa, yield strength 860-1240MPa, elongation ≥ 10%, hardness (HRC) 30-45, and excellent balance of strength and toughness.

Corrosion resistance: superior to ordinary martensitic stainless steel, resistant to atmospheric, freshwater, and neutral salt solution corrosion, with good resistance to slightly corrosive media, suitable for outdoor or humid conditions.

Processing and forging characteristics: The forging temperature range is 1100-1200 ℃, and the hot processing performance is good. It can be forged into complex forgings such as shafts, rollers, and sleeves; After cold processing, it is necessary to promptly perform solution treatment to avoid residual stress.

Stability: After aging treatment, the organization is stable, and good mechanical properties are maintained at high temperatures without obvious aging softening phenomenon, suitable for applications in medium and low temperature conditions.

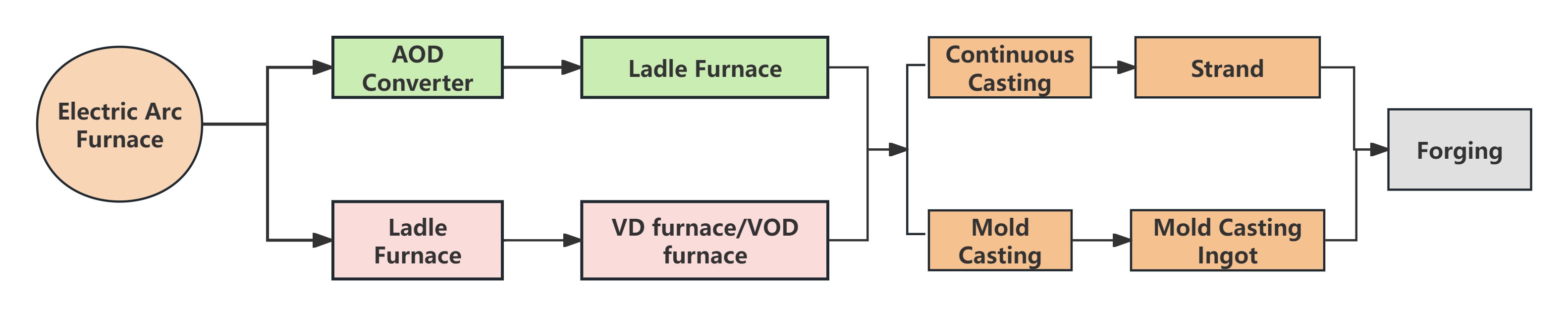

Production Procedure

Mechanical Property and Heat Treatment

The core mechanical properties of 15-5PH stainless steel are high strength and good toughness.

H900 (aging temperature 482℃): yield strength ≥1100MPa, tensile strength ≥1240MPa, elongation ≥10%, hardness ≥38HRC.

H1025 (aging temperature 552℃): yield strength ≥1030MPa, tensile strength ≥1170MPa, elongation ≥12%, hardness ≥35HRC.

H1150 (aging temperature 621℃): yield strength ≥860MPa, tensile strength ≥965MPa, elongation ≥15%, hardness ≥30HRC.

H1150M (aging + stabilization): yield strength ≥790MPa, tensile strength ≥930MPa, elongation ≥18%, superior toughness (impact energy ≥54J).

Delivery condition

Forging + black

Forging + peeled surface

Forging + solution + peeled surface

Forging + solution + aging + peeled surface