FORGE-BLOCK

ETERNAL

5CrNiMoV is a hot work die steel specified in the Chinese national standard (GB/T 1299-2014). It adds a small amount of vanadium (V) element to the classic 5CrNiMo steel, significantly improving the tempering stability, thermal strength, and wear resistance of the steel.

5CrNiMoV Chemical Composition

| C | Si | Mn | Cr | Ni | Mo | V | P | S |

| 0.5-0.6% | 0.15-0.4% | 0.5-0.8% | 0.8-1.1% | 1.4-1.8% | 0.3-0.5% | 0.15-0.3% | ≤0.03% | ≤0.03% |

Carbon (C) 0.50-0.60%: ensures the hardenability and hardness of the steel, providing good wear resistance.

Chromium (Cr)&Molybdenum (Mo): Their main function is to improve the hardenability, tempering stability, and

thermal strength of steel. Molybdenum can also effectively prevent temper brittleness.

Nickel (Ni): significantly improves the toughness and plasticity of steel, preventing brittle fracture of molds under huge impact loads.

Vanadium (V) 0.15-0.30%: (This is the main difference from 5CrNiMo) Vanadium can refine grains, form carbides, and significantly improve the wear resistance, thermal hardening, and thermal fatigue resistance of steel.

Silicon (Si)&Manganese (Mn): Assisted Deoxygenation and Alloying to Improve Strength

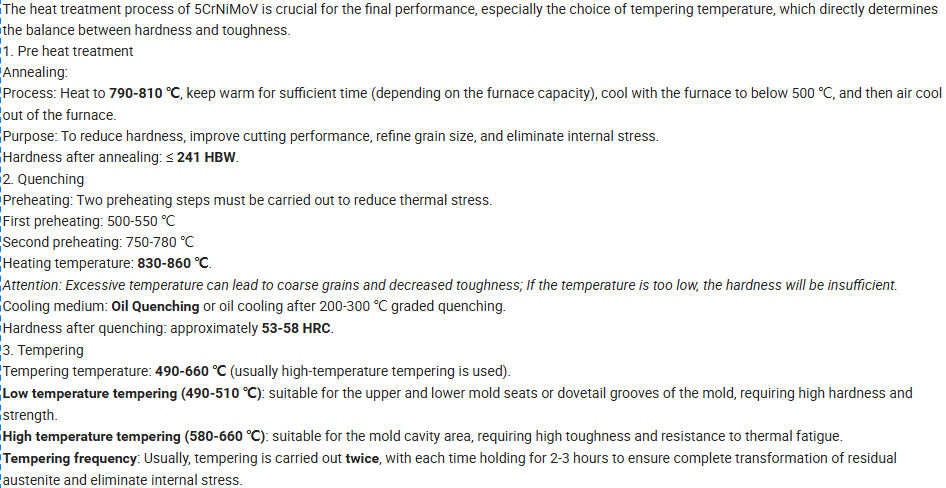

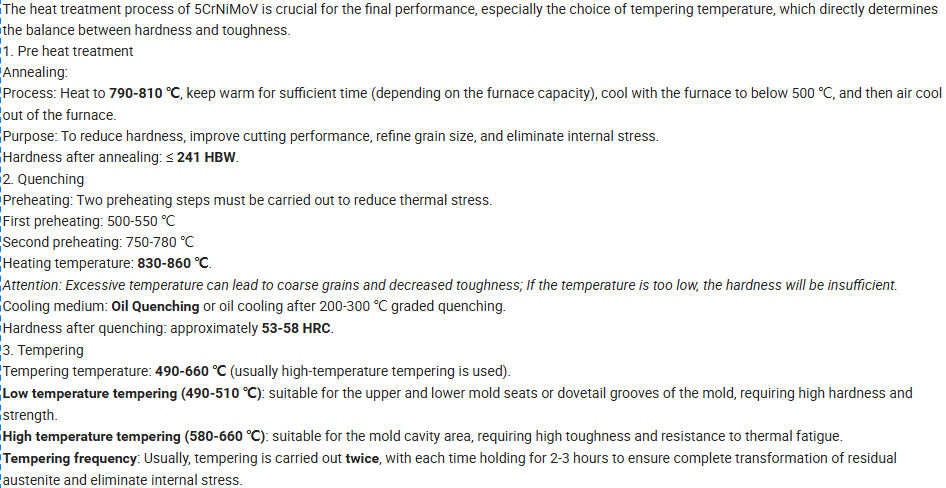

Heat treatment

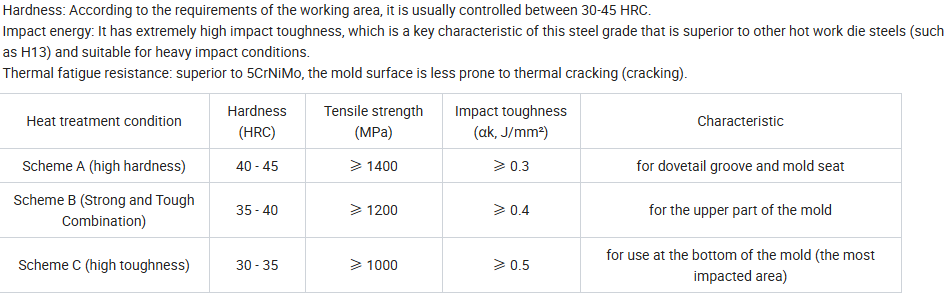

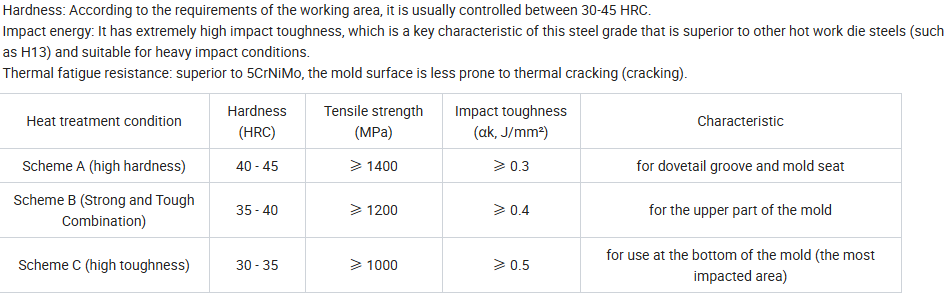

Mechanical Property

Feature

The function of vanadium (V): Compared to 5CrNiMo, 0.15% -0.30% vanadium is added. Vanadium can refine grain size, form hard carbides, and significantly improve the wear resistance, thermal strength (ability to maintain hardness at high temperatures), and tempering stability of steel.

High toughness: The combination of nickel (Ni) and chromium (Cr) ensures that the material has extremely high impact toughness, preventing brittle fracture of the mold under impact loads (such as hammer forging).

Good hardenability: It can be hardened by air cooling, and even for large molds (with a cross-sectional thickness of over 400mm), uniform structure and properties can be obtained.

Application

Large hammer forging die: This is its main use, especially for the middle and lower parts of the mold cavity, to withstand severe impact and friction.

Hot extrusion mold: used for extruding black or non-ferrous metals.

Precision forging molds: occasions that require high dimensional accuracy and wear resistance.

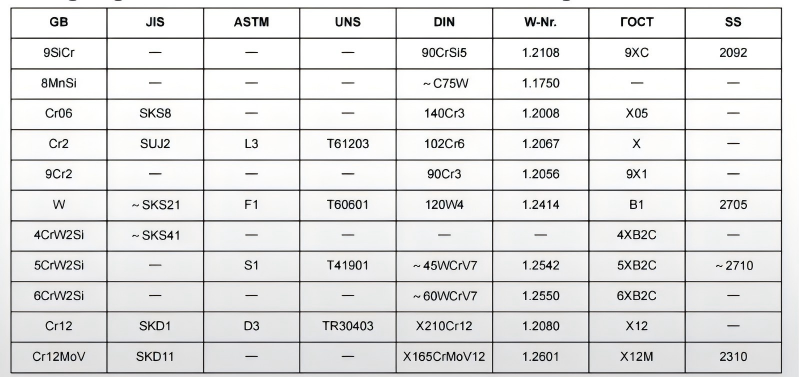

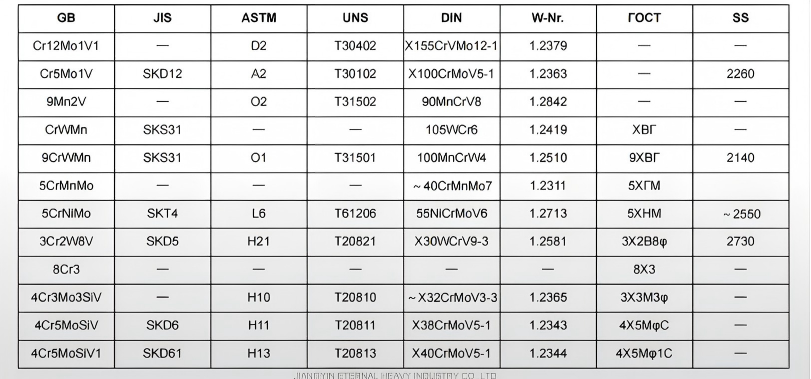

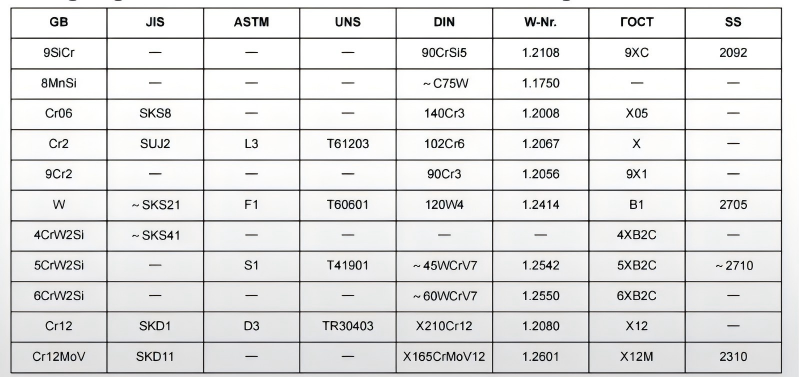

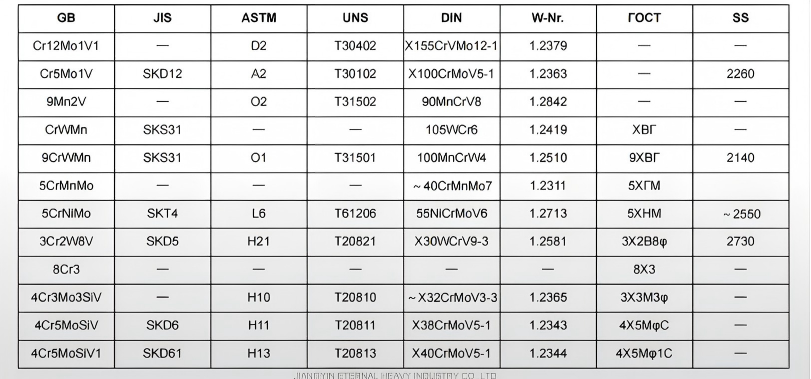

Common Die Steel Steel Grade

5CrNiMoV is a hot work die steel specified in the Chinese national standard (GB/T 1299-2014). It adds a small amount of vanadium (V) element to the classic 5CrNiMo steel, significantly improving the tempering stability, thermal strength, and wear resistance of the steel.

5CrNiMoV Chemical Composition

| C | Si | Mn | Cr | Ni | Mo | V | P | S |

| 0.5-0.6% | 0.15-0.4% | 0.5-0.8% | 0.8-1.1% | 1.4-1.8% | 0.3-0.5% | 0.15-0.3% | ≤0.03% | ≤0.03% |

Carbon (C) 0.50-0.60%: ensures the hardenability and hardness of the steel, providing good wear resistance.

Chromium (Cr)&Molybdenum (Mo): Their main function is to improve the hardenability, tempering stability, and

thermal strength of steel. Molybdenum can also effectively prevent temper brittleness.

Nickel (Ni): significantly improves the toughness and plasticity of steel, preventing brittle fracture of molds under huge impact loads.

Vanadium (V) 0.15-0.30%: (This is the main difference from 5CrNiMo) Vanadium can refine grains, form carbides, and significantly improve the wear resistance, thermal hardening, and thermal fatigue resistance of steel.

Silicon (Si)&Manganese (Mn): Assisted Deoxygenation and Alloying to Improve Strength

Heat treatment

Mechanical Property

Feature

The function of vanadium (V): Compared to 5CrNiMo, 0.15% -0.30% vanadium is added. Vanadium can refine grain size, form hard carbides, and significantly improve the wear resistance, thermal strength (ability to maintain hardness at high temperatures), and tempering stability of steel.

High toughness: The combination of nickel (Ni) and chromium (Cr) ensures that the material has extremely high impact toughness, preventing brittle fracture of the mold under impact loads (such as hammer forging).

Good hardenability: It can be hardened by air cooling, and even for large molds (with a cross-sectional thickness of over 400mm), uniform structure and properties can be obtained.

Application

Large hammer forging die: This is its main use, especially for the middle and lower parts of the mold cavity, to withstand severe impact and friction.

Hot extrusion mold: used for extruding black or non-ferrous metals.

Precision forging molds: occasions that require high dimensional accuracy and wear resistance.

Common Die Steel Steel Grade