| Availability: | |

|---|---|

| Quantity: | |

FORGE-FLANGE

ETERNAL

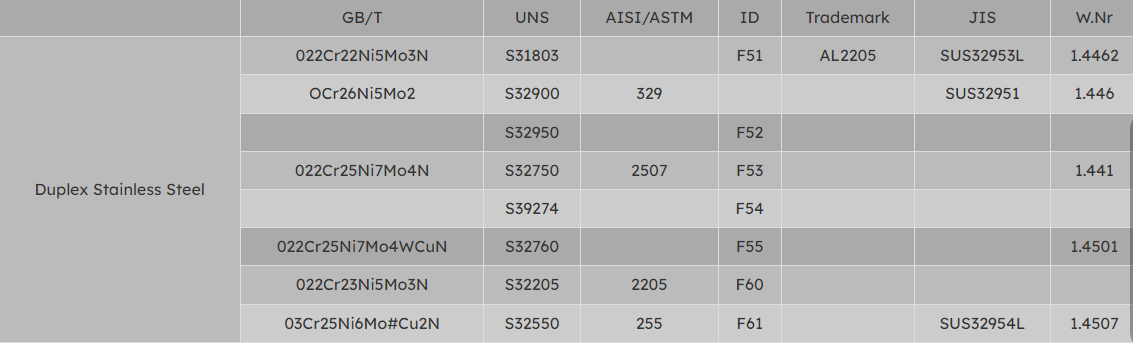

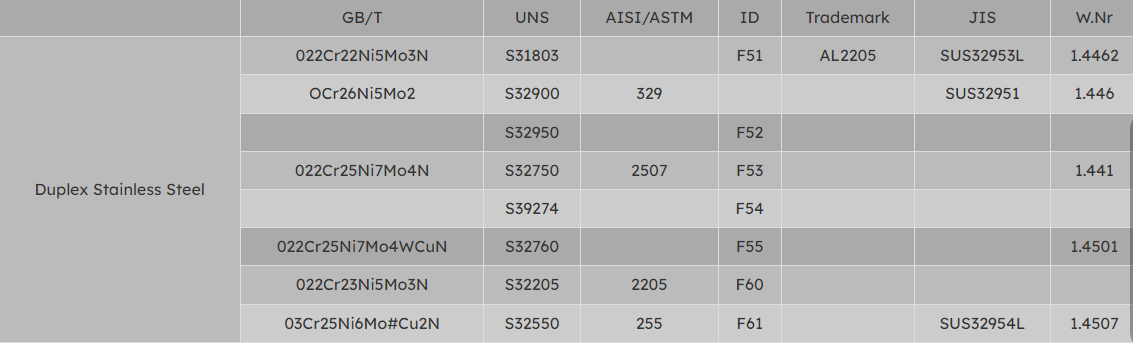

F60 stainless steel, also known as 2205 duplex stainless steel, has a material standard of ASTM A182, corresponding to UNS number S32205, and German material number 1.4462. This ingredient gives it high strength and good corrosion resistance.

F60 and Other Similar Duplex Stainless Steel Material Steel Grade

F60 Chemical Compisition

| Steel Grade | Chemical Composition(%) | ||||||||

| C | Si | Mn | P | S | Cr | Mo | Ni | N | |

| F60 | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.020 | 22.0-23.0 | 3.0-3.5 | 4.5-6.5 | 0.14-0.20 |

F60 Heat Treatment

The core goal of heat treatment for F60 duplex stainless steel is to achieve a balanced austenite ferrite duplex structure, while eliminating forging stress, improving corrosion resistance and mechanical properties.

Solution heat treatment

Heating temperature: 1020-1100 ℃, commonly used temperature is 1050-1080 ℃. Low temperature can lead to an imbalance in the ratio of two phases and the precipitation of carbides; Excessive temperature can cause coarsening of ferrite grains and reduce toughness.

Insulation time: determined based on the effective thickness of the flange, generally calculated at 2-4 minutes/mm to ensure uniform heating of the material.

Cooling mode: forced water cooling (preferred) or spray cooling. The cooling speed should be fast enough to prevent carbide precipitation at grain boundaries and reduce corrosion resistance and toughness. Air cooling or slow cooling is strictly prohibited, otherwise it will increase the sensitivity of intergranular corrosion.

Stress relief annealing

If the flange undergoes subsequent organic processing or welding, stress relief annealing can be performed after solution treatment at a temperature of 200-300 ℃, followed by air cooling after insulation.

F60 Mechanical Property

The mechanical properties of F60 duplex stainless steel forged flanges must meet the requirements of ASTM A182 standard, with typical indicators as follows (at room temperature):

Tensile strength (Rm) ≥ 620 MPa

Yield strength (Rp0.2) ≥ 450 MPa

Elongation rate (A) ≥ 25%

Sectional shrinkage rate (Z) ≥ 45%

Hardness (HB) ≤ 290

Impact energy (KV, -40 ℃) ≥ 40 J

F60 Stainless Steel Flange Application

The F60 stainless steel forged flange, with its core characteristics of strong corrosion resistance and high strength, is mainly used in various harsh working conditions containing chlorides and acidic/alkaline media.

1.Offshore platforms and acid oil and gas field pipeline connections in the field of oil and gas;

2.Flanges for corrosive medium transportation and reaction equipment in the chemical and petrochemical industry;

3.Seawater desalination and seawater contact systems for marine engineering;

4.Thermal power plant flue gas desulfurization system and nuclear power auxiliary cooling system;

5.The bleaching and steaming equipment in the paper industry, as well as the salt/acid working conditions in the food and pharmaceutical industry.

F60 Stainless Steel Flange Feature

Excellent mechanical properties: The dual phase structure of austenite and ferrite makes its yield strength about twice that of ordinary austenitic stainless steel, with strong compressive and load resistance, as well as good plasticity and toughness.

Outstanding corrosion resistance: It has better resistance to pitting corrosion, crevice corrosion, and stress corrosion cracking in chloride media than 316L, and is suitable for corrosive working conditions.

Excellent forging quality: After forging, the grain size is refined, the structure is dense, the dimensional accuracy and surface quality are controllable, and the yield of finished products is high.

Moderate temperature resistance range: It can be used for a long time at -50 ℃~300 ℃, with no brittle fracture at low temperatures, stable performance at medium temperatures, and easy tissue degradation at high temperatures.

High cost-effectiveness: Although the raw material cost is high, high strength can reduce the thickness of thin walls, and the comprehensive cost of high-pressure and large-diameter scenarios is better.

Anti fatigue and wear-resistant: It has a longer service life under alternating loads and slight wear conditions.

F60 stainless steel, also known as 2205 duplex stainless steel, has a material standard of ASTM A182, corresponding to UNS number S32205, and German material number 1.4462. This ingredient gives it high strength and good corrosion resistance.

F60 and Other Similar Duplex Stainless Steel Material Steel Grade

F60 Chemical Compisition

| Steel Grade | Chemical Composition(%) | ||||||||

| C | Si | Mn | P | S | Cr | Mo | Ni | N | |

| F60 | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.030 | ≤0.020 | 22.0-23.0 | 3.0-3.5 | 4.5-6.5 | 0.14-0.20 |

F60 Heat Treatment

The core goal of heat treatment for F60 duplex stainless steel is to achieve a balanced austenite ferrite duplex structure, while eliminating forging stress, improving corrosion resistance and mechanical properties.

Solution heat treatment

Heating temperature: 1020-1100 ℃, commonly used temperature is 1050-1080 ℃. Low temperature can lead to an imbalance in the ratio of two phases and the precipitation of carbides; Excessive temperature can cause coarsening of ferrite grains and reduce toughness.

Insulation time: determined based on the effective thickness of the flange, generally calculated at 2-4 minutes/mm to ensure uniform heating of the material.

Cooling mode: forced water cooling (preferred) or spray cooling. The cooling speed should be fast enough to prevent carbide precipitation at grain boundaries and reduce corrosion resistance and toughness. Air cooling or slow cooling is strictly prohibited, otherwise it will increase the sensitivity of intergranular corrosion.

Stress relief annealing

If the flange undergoes subsequent organic processing or welding, stress relief annealing can be performed after solution treatment at a temperature of 200-300 ℃, followed by air cooling after insulation.

F60 Mechanical Property

The mechanical properties of F60 duplex stainless steel forged flanges must meet the requirements of ASTM A182 standard, with typical indicators as follows (at room temperature):

Tensile strength (Rm) ≥ 620 MPa

Yield strength (Rp0.2) ≥ 450 MPa

Elongation rate (A) ≥ 25%

Sectional shrinkage rate (Z) ≥ 45%

Hardness (HB) ≤ 290

Impact energy (KV, -40 ℃) ≥ 40 J

F60 Stainless Steel Flange Application

The F60 stainless steel forged flange, with its core characteristics of strong corrosion resistance and high strength, is mainly used in various harsh working conditions containing chlorides and acidic/alkaline media.

1.Offshore platforms and acid oil and gas field pipeline connections in the field of oil and gas;

2.Flanges for corrosive medium transportation and reaction equipment in the chemical and petrochemical industry;

3.Seawater desalination and seawater contact systems for marine engineering;

4.Thermal power plant flue gas desulfurization system and nuclear power auxiliary cooling system;

5.The bleaching and steaming equipment in the paper industry, as well as the salt/acid working conditions in the food and pharmaceutical industry.

F60 Stainless Steel Flange Feature

Excellent mechanical properties: The dual phase structure of austenite and ferrite makes its yield strength about twice that of ordinary austenitic stainless steel, with strong compressive and load resistance, as well as good plasticity and toughness.

Outstanding corrosion resistance: It has better resistance to pitting corrosion, crevice corrosion, and stress corrosion cracking in chloride media than 316L, and is suitable for corrosive working conditions.

Excellent forging quality: After forging, the grain size is refined, the structure is dense, the dimensional accuracy and surface quality are controllable, and the yield of finished products is high.

Moderate temperature resistance range: It can be used for a long time at -50 ℃~300 ℃, with no brittle fracture at low temperatures, stable performance at medium temperatures, and easy tissue degradation at high temperatures.

High cost-effectiveness: Although the raw material cost is high, high strength can reduce the thickness of thin walls, and the comprehensive cost of high-pressure and large-diameter scenarios is better.

Anti fatigue and wear-resistant: It has a longer service life under alternating loads and slight wear conditions.