Views: 0 Author: Site Editor Publish Time: 2026-01-23 Origin: Site

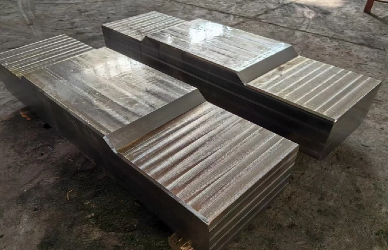

Hot work tool steels, such as H13 (1.2344), are critical materials used in industries like forging, die-casting, and extrusion, where tools are exposed to high temperatures, mechanical stresses, and thermal cycles. These steels are specifically designed to withstand the harsh conditions of hot working processes, ensuring the durability and performance of molds, dies, and other tooling components. H13 is particularly valued for its superior wear resistance, making it ideal for applications where tools are subjected to constant friction and abrasion. Additionally, H13 boasts excellent thermal fatigue resistance, allowing it to endure the repeated heating and cooling cycles encountered in high-temperature operations without cracking. Its high-temperature strength further enhances its performance, ensuring it maintains its hardness and toughness even under extreme conditions. These key properties make H13 an essential material for industries that rely on high-performance tooling for precision and longevity in their manufacturing processes.

Proper heat treatment is crucial in extending the service life of H13 steel, as it directly affects the material’s hardness, toughness, and wear resistance. By carefully controlling the heat treatment processes, manufacturers can enhance the performance of H13 in high-temperature applications like forging, die-casting, and extrusion.

The first step in heat treatment is quenching, which involves heating H13 steel to a high temperature (usually around 1050°C to 1100°C) and then rapidly cooling it, typically in oil or air. This process hardens the steel by transforming its microstructure, improving its wear resistance and strength. Quenching is essential to ensure that H13 can withstand the high pressures and friction encountered in tooling applications.

After quenching, H13 steel undergoes tempering to relieve internal stresses and adjust its hardness. Tempering involves reheating the steel to a lower temperature (typically between 500°C and 650°C) and holding it there for a specified time. This process increases toughness while reducing the brittleness that may result from the quenching process. Tempering also helps to maintain the high-temperature strength of H13, allowing it to endure extreme thermal conditions without losing its hardness.

In some cases, especially for certain tool manufacturing processes, annealing is performed after quenching to refine the microstructure and enhance machinability. Annealing involves heating the steel to a specific temperature, usually around 800°C to 850°C, and slowly cooling it. This process softens the steel, making it easier to machine before final tempering.

Maintaining the correct forging temperatures and operating conditions is critical to extending the service life of H13 steel. The right temperatures ensure that H13 maintains its wear resistance, thermal stability, and overall performance while avoiding premature failure due to excessive wear or thermal fatigue.

For H13 steel, the forging temperature range typically falls between 1050°C to 1200°C. This range is crucial because it ensures that the steel’s microstructure remains stable while allowing for the required plasticity during forging processes. At temperatures too low, H13 may not form properly, leading to cracks or uneven wear. Conversely, if the steel is forged at temperatures above 1200°C, it can experience grain growth, weakening its strength and making it more susceptible to damage.

Maintaining the correct forging temperature within this range helps ensure that the material retains its strength and toughness, preventing premature wear, thermal fatigue, and cracking during high-temperature operations.

Overheating H13 steel above the recommended forging temperature range can have detrimental effects on its microstructure, leading to coarse grains, reduced toughness, and poor wear resistance. Excessive heat exposure can also cause the formation of undesirable phases in the steel, which can compromise its performance in high-stress applications. Additionally, overheating can make the steel more prone to thermal fatigue when exposed to repeated heating and cooling cycles.

The cooling rate is also a crucial factor in ensuring H13’s longevity. After forging, cooling should be controlled to prevent thermal shock, which can cause cracking or warping of the steel. Rapid cooling, such as quenching in water or oil, may lead to thermal stresses if not managed properly. Controlled cooling, such as air cooling or using specific cooling mediums, helps reduce these stresses and allows the steel to cool uniformly, preserving its hardness and toughness.

A gradual and uniform cooling process is essential to avoid the development of internal stresses, ensuring that H13 maintains its strength and wear resistance over time, even under high thermal cycling conditions.

Regular maintenance and inspection are crucial for extending the service life and ensuring the optimal performance of H13 steel in high-temperature applications. Routine checks help detect early signs of wear, cracks, and thermal fatigue that could compromise tooling effectiveness.

Routine maintenance helps to:

Monitor Wear: H13 steel undergoes abrasive wear over time. Regular checks help identify worn areas for timely repairs or replacements.

Detect Cracks and Deformation: Thermal fatigue can cause microcracks. Early detection prevents failure and ensures the mold remains operational.

Identify Thermal Fatigue: Repeated thermal cycling can weaken the steel. Regular inspections can detect early signs of thermal damage before it becomes critical.

Non-destructive testing (NDT) methods allow for early detection of issues without damaging the material. Common NDT methods include:

Ultrasonic Testing (UT): Detects internal flaws such as cracks or voids.

Magnetic Particle Testing (MT): Identifies surface cracks in ferromagnetic materials like H13.

Dye Penetrant Testing (DPT): Highlights surface cracks or defects.

X-Ray Testing (RT): Reveals internal structural issues like voids.

Prolong Tool Life: Detecting issues early extends the lifespan of tooling components.

Reduce Downtime: Timely intervention prevents unexpected failures, minimizing production interruptions.

Improve Safety: Ensures tooling integrity, reducing the risk of accidents.

Surface treatments and protective coatings are crucial for enhancing H13 steel’s wear resistance and thermal stability, extending its service life in high-temperature environments.

Carburizing: Adds carbon to the surface, forming a hard, wear-resistant layer while maintaining core toughness. Ideal for high-wear applications like die-casting molds.

Nitriding: Introduces nitrogen to create a hard, abrasion-resistant surface layer. Enhances wear and corrosion resistance, ideal for applications requiring surface hardness.

Thermal Barrier Coatings (TBCs): Reflects heat, reducing direct exposure to high temperatures, preserving material integrity and extending tool life.

Chromium and Ceramic Coatings: Provides abrasion and oxidation resistance, ideal for extrusion dies or hot stamping molds.

Enhanced Wear Resistance: Reduces wear, extending tool life.

Thermal Protection: Minimizes thermal fatigue and oxidation.

Corrosion Resistance: Prevents corrosion, maintaining tool integrity.

Proper lubrication and cooling systems are essential for maintaining H13 steel's performance and extending its service life in high-temperature operations by reducing friction and preventing thermal damage.

Lubrication reduces friction, preventing wear and heat buildup. It also forms a protective film, preventing seizing or galling under high pressure, which helps maintain steel hardness and thermal stability.

Cooling systems ensure consistent temperature control, preventing thermal fatigue and thermal shock:

Temperature Regulation: Cooling prevents overheating, reducing hot spots and thermal cracking.

Prevent Thermal Shock: Controlled cooling reduces rapid temperature fluctuations, maintaining toughness and crack resistance.

Water-Based Coolants: Excellent cooling but may cause corrosion if not managed properly.

Oil-Based Coolants: Better for lubrication and cooling, ideal for high-friction applications.

Synthetic Coolants: Offer a balance of lubrication and cooling, reducing wear and residue buildup.

Reduced Friction: Extends tool life by minimizing wear.

Prevents Overheating: Maintains thermal stability and prevents thermal fatigue.

Improved Tool Life: Minimizes downtime and maintenance costs.

The ideal heat treatment for H13 involves quenching at 1050°C to 1100°C and tempering between 500°C to 650°C to achieve optimal hardness.

Overheating can lead to grain growth, reducing toughness and strength, making the steel more prone to wear and thermal fatigue.

Nitriding or carburizing H13 can improve surface hardness and resistance to abrasion, helping to extend tool life in high-wear environments.

Routine inspections using non-destructive testing methods help detect cracks or wear early, preventing unexpected failures and extending the life of the tools.

To extend the service life of H13 steel and maintain its performance in high-temperature applications, it is essential to follow a combination of key strategies. Proper heat treatment—including quenching, tempering, and annealing—ensures optimal hardness and toughness. Maintaining optimal operational conditions such as the correct forging temperatures and cooling rates prevents thermal fatigue and reduces the risk of wear. Regular maintenance and inspection help detect wear, cracks, and thermal damage early, ensuring timely repairs. Additionally, surface treatments like carburizing, nitriding, and protective coatings provide extra protection against abrasion and corrosion, enhancing wear resistance and thermal stability. Finally, selecting the right practices based on the specific application needs—whether the focus is on wear resistance, thermal stability, or impact toughness—will ensure the longevity and reliability of H13 tooling in demanding environments.